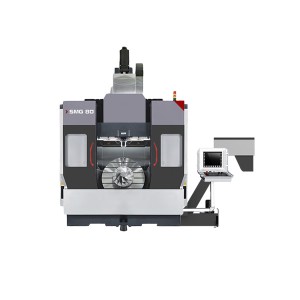

TIANSHUI SPARK 5-Axis Machining Center CNCX850

|

Item |

CNCX850 |

|

Max. swing diameter over bed |

Φ850 mm |

|

Max. machining diameter of tool holder |

Φ850 mm |

|

Max. length of processed workpiece |

2000 mm |

|

Max. weight of processed workpiece |

1000 kg |

|

Spindle nose standard |

ISO A2-11 |

|

Spindle front bearing diameter |

Φ170 mm |

|

Spindle through-hole diameter |

Φ100 mm |

|

Spindle hydraulic chuck |

15” |

|

Max. spindle speed |

2000 rpm |

|

Max. output torque of the spindle |

2000 Nm |

|

Spindle servo motor power |

39 kw |

|

C-axis Max. speed |

20 rpm |

|

C-axis Max. torque |

2000 Nm |

|

Minimum programming increment for C-axis |

0.0001° |

|

Sub spindle end standard |

ISO A1-8 |

|

Sub spindle through-hole diameter |

Φ105 mm |

|

Max. output torque of the sub spindle |

800 Nm |

|

Milling spindle power |

S1 100% 22 kw |

|

S6 40% 30 kw |

|

|

Max. speed of milling head |

4000 rpm |

|

Max. torque of milling head |

S1 100% 200 Nm |

|

S6 40% 300 Nm |

|

|

B-axis swing angle |

320°(angle of milling cutter ± 160 °) |

|

B-axis indexing positioning |

2.5° |

|

B-axis swing torque |

1100 Nm |

|

B-axis Max. clamping torque |

3500 Nm |

|

B-axis Min. programming increment |

0.0001° |

|

Z-axis travel (longitudinal) |

2050 mm |

|

X-axis travel (vertical) |

+600 /-50 mm |

|

Y-axis travel (transverse) |

400(±200) mm |

|

W-axis travel (sub spindle box) |

1500 mm |

|

Z-axis rapid traverse speed |

12 m/min |

|

X-axis rapid traverse speed |

12 m/min |

|

Y-axis rapid traverse speed |

12 m/min |

|

W-axis rapid traverse speed |

12 m/min |

|

Tool system |

HSK 63A |

|

Number of tool magazine |

36 pcs |

|

Max. tool diameter (when adjacent positions are full) |

Φ100mm |

|

Max. tool weight |

7 Kg |

|

Machine tool dimensions |

13.1 x 3.3 x3.1 m |

|

Machine center height |

1250 mm |

|

Total weight of machine tool |

20000 kg |

|

Control system |

HUAZHONG HNC-840DI |

The structural characteristics of the equipment profile

1、Basic parts

CNCX850 turning and milling complex machining center can realize a variety of machining operations in various industries; the machine tool can carry out machining operations such as turning, planing, grooving, milling groove, tooth cutting, etc.; the surface roughness of the workpiece can be even lower than Ra0.4; the turning accuracy can reach 0.005 mm; hard materials such as nickel-chromium (alloy) can be processed; the working head can be tilted and can be moved throughout the working area.

The machine bed adopts resin sand molding and high quality cast iron casting, which has good appearance and strength, reasonable layout of the ribbed plate, dendritic reinforcement makes the bed have excellent stiffness, vibration resistance and anti-sectional distortion ability, and the cavity adopts sand sealing structure, which increases the overall damping of the bed and effectively improves the vibration resistance of the machine. The bed adopts 45° overall inclined bed structure. The machine tool adopts turning and milling spindle to realize high torque cutting of keyway, hexagon and gear.

The main supporting parts of the machine tool are all world famous brands: spindle and tailstock bearing selected from Japan NSK, ball screw selected from Japan THK, screw support bearing selected from Japan NSK, roller heavy-duty linear guide selected from Germany INA, B axis selected from France SOMAB, hydraulic chuck selected from Shanghai Sanliu, tool setting instrument and automatic measuring device selected from Italy MARPOSS, circular scale selected from Germany HEIDENHAIN, Spain FAGOR for each feed axis scale, Taiwan GIFU for tool magazine, Nanjing Bechtel for centralized lubrication system, China for pneumatic system and hydraulic system, Huazhong NC for CNC system and spindle motor and each axis feed servo motor. The feed axes are fully closed-loop control.

Machine design and manufacturing accuracy should be in line with the corresponding national standards, fully enclosed protection device in line with GB15760-2004 related national standards.

The operating system is HNC848DI CNC system; X, Y, Z, B, C axis adopts imported scales, linear scale resolution ≤ 0.001mm, circular scale resolution: 0.0001°.

2、Double spindle

Spindle box for the overall structure, spindle using two-point support, spindle bearings using imported original Japanese NSK double-row angular contact spindle special bearings, reasonable span design, and spindle parts by dynamic balance treatment plus high-precision imported bearings reasonable grouping, making the spindle has a high rigidity, excellent rotary accuracy and low temperature rise performance. The spindle box has low noise and high transmission precision. The spindle box adopts the form of high-speed grease lubrication.

The spindle is driven by 38KW spindle servo motor produced by Huazhong NC, and the power is transmitted to the spindle through high wear-resistant belt to make the spindle reach the specified torque and 2000rpm maximum speed. The spindle is equipped with circular scale to improve the spindle for indexing and positioning (C-axis) function and indexing accuracy, and also to realize the programming control of feed per revolution and constant linear speed cutting. The spindle has a large variable speed range, high transmission accuracy, excellent power and torque characteristics, high speed, smooth transmission, and compact structure. The machine has electrical overload protection device, mechanical overload protection device and emergency stop device to control spindle rotation.

The main drive and “C-axis” feeding technology are integrated. The spindle with C-axis function can realize the regular cutting rotary motion and C-axis feeding motion.

The spindle is equipped with a three-jaw self-centering solid hydraulic power chuck (three-six chuck) with a chuck diameter of φ400mm and one set of soft and hard jaws each.

Equipped with a sub-spindle box with A1 8″ spindle motor mounted on a CNC controlled longitudinal trailing plate (W axis). (W axis) The longitudinal program-controlled feed motion of the sub-spindle box is realized by a 4 N.m AC servo motor with stepless speed-regulated rapid traverse and feed motion through a rack-and-pinion sub. Sub-spindle box and bed locking can be programmed to complete.

3、 Tool magazine

The machine tool is equipped with a tool magazine with 28 tool positions. The tool changer is located in the upper part of the spindle box, which can access the tools automatically and is convenient and simple to operate.

4、X、Y、Z、B、C axis

4.1 X, Y, Z axis

Z-axis, X-axis and Y-axis feed motion are driven by Huazhong NC AC servo motor to drive THK precision ball screw subsets to achieve stepless speed-adjustable rapid traverse and feed motion, and use high-precision linear scale to achieve full closed-loop control of Z, X and Y axes.

The screw is supported by two sets of ball screw special 60° angular contact ball bearings in a face-to-face assembly, forming a “fixed-fixed” support method. The ball screw has high precision and axial stiffness after pre-tightening and pre-tensioning.

Each guideway adopts the original imported German INA roller heavy-duty linear guide, which has the characteristics of low friction coefficient, fast moving speed, fast response to the control system and good precision maintenance.

X, Y and Z axes have soft limits, hardware limits controlled by travel switches and mechanical limits (in both positive and negative directions).

4.2 B-axis:

B-axis adopts the original imported high-performance B-axis made by SOMAB of France, which is equipped with HSK standard interface. In appearance, it has a small form factor, increases the available space inside the machine tool, can swing the angle freely in both directions, has high positioning and repeat positioning accuracy, very low failure rate and good rigidity and life.

The head is equipped with a fixture to hold the turning tool and a rotating arbor to hold the milling tool.

The head is compact and rigid. The entire working head is firmly fitted to the rotating B-axis. It is capable of continuous rotation within 320° (milling tool turning angle ±160°) at a speed of 0 to 30 rpm. The B-axis drive has no clearance and uses an angle grating to measure positioning (resolution: 0.0001°). It can be used in any fixed position or as a rotating axis. In this way, compound machining and five-axis linkage are realized.

The mechanical coupling device inside the work head is indexed in 2.5° to ensure good tool positioning accuracy, repeatable positioning accuracy, and high stiffness. This allows the high precision to be maintained even when machining with long boring bars.

For turning fixtures, turning tools have a tightening locking device. The optimum angle of the working head is 45° when using shorter tools for turning external circles or end faces. The fixture for clamping turning tools holds HSK toolholders. This fixture has an external cooling system and a cooling system that leads to the inside of the turning tool. In any working position, this cooling system can be used separately or simultaneously. When changing tools, the tapered hole and the toolholder can be cleaned with an internal air blower.

A rotary arbor for milling, which can be matched to the HSK tool unit. The rotary arbor can be used at speeds of up to 4000 rpm. It also has an external cooling system and a cooling system to the inside of the tool. This cooling system can withstand a pressure of 20 bar. In any working position, the cooling system can be used separately or simultaneously. When changing the tool, an internal air blower can be used to clean the tapered hole and the tool shank.

5、Hydraulic system:

Hydraulic system is used to achieve hydraulic chuck clamping and loosening action, the installation of brake damping mechanism on the spindle box can make the machine tool spindle in operation to increase a certain damping and rapid braking in high-speed rotation, to achieve the purpose of re-elimination of vibration, can improve the cutting performance of the machine tool. Hydraulic also realize the B-axis clamping and unclamping, milling tool unclamping, turning tool unclamping and other functions. The hydraulic pipeline is protected by steel drag chain.