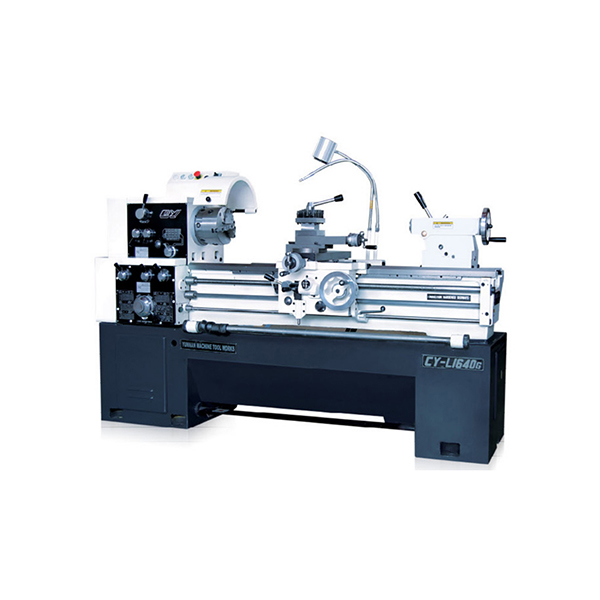

YUNNAN High Speed Gap Bed Lathe CY-L1630G CY-L1640G CY-L1660G

Characteristic

The headstock, gear-box. apron and bed-ways are made of high quality cast iron, and they are all cast with the resin sand foundry technology.

The hardness of induction hardened bed-ways is around HRC 52.

The lathe is featured of high efficiency, high precision, high rigidity and excellent cutting performance.

The base of the bed is cast into mono block with a chip space. The structure ensures high rigidity of the whole machine and convenient chip disposal.

The spindle supported by 3-pointed high-precision bearings and all gears in headstock are precisely grinded, the spindle turns smoothly at high speed.

Foot brake, overload protection, chip guard, longitudinal automatic stop device, point-to-point control in spindle, manual lubrication pump, ensures easy operation and good performance of the machine.

|

Items |

Unit |

CY-L1630G |

CY-L1640G |

CY-L1660G |

|

Swing over bed |

mm |

410 |

||

|

Swing over cross slide |

mm |

258 |

||

|

Distance between centers |

mm |

750 |

1000 |

1500 |

|

Swing in gap |

mm |

580 |

||

|

Width of gap |

mm |

250 |

||

|

Width of bed |

mm |

274 |

||

|

Spindle nose |

|

D6 |

||

|

Spindle bore diameter |

mm |

52 |

||

|

Morse taper of spindle center |

|

M6 |

||

|

Spindle speed |

rpm |

33-2000 rpm (16 steps) |

||

|

Inch system threads |

t.p.i. |

4-56 |

||

|

Metric threads |

mm |

0.5-7 |

||

|

Range of longitudinal feed |

mm/rev |

0.087-1.22 |

||

|

Range of cross feed |

mm/rev |

0.066-0.931 |

||

|

Lead screw diameter |

mm |

28 |

||

|

Lead screw pitch |

|

6 mm ( Metric system) 4 t.p.i. Inch system) |

||

|

Morse taper of tailstock center |

|

M4 |

||

|

Cross slide travel |

mm |

220 |

||

|

Top slide travel |

mm |

100 |

||

|

Max travel of tailstock quill |

mm |

100 |

||

|

Tailstock quill diameter |

mm |

52 |

||

|

Main motor |

kw |

3/4.5 |

||

|

Coolant pump motor |

kw |

0.1 |

||

|

Machine size (LxWxH) |

mm |

1820x1040x1700 |

2070x1040x1700 |

2570x1040x1700 |

|

GW/NW(KGS) |

kg |

1800/1300 |

2000/1400 |

2500/1700 |

|

Package dimensions |

mm |

2020x1120x1820 |

2280x1120x1820 |

2750x1120x1820 |

Stander Configuration

1. 200mm 3-jaw chuck

2. Thread chasing dial

3. Chip guard

4. Chuck cover

5. Foot brake

6. Oil gun

7. Live Center 4#

8. Center 4#

9. Center sleeve

Optional Configuration

1. 400mm Face plate

2. 250mm 4-jaw chuck

3. 20-120mm Small Steady rest

90-200mm Large Steady rest

4. 20-60mm Follow rest

5. 190mm Drive plate

6. 4-position stop for saddle

7. 4-position stop for cross slide

8. Micro stop for saddle

9. Quick change tool post

10. Damping washer

11. Taper turning attachment(TTA)

12. Halogen work lamp

13. Digital readout(DRO)

14. CE standard compliance