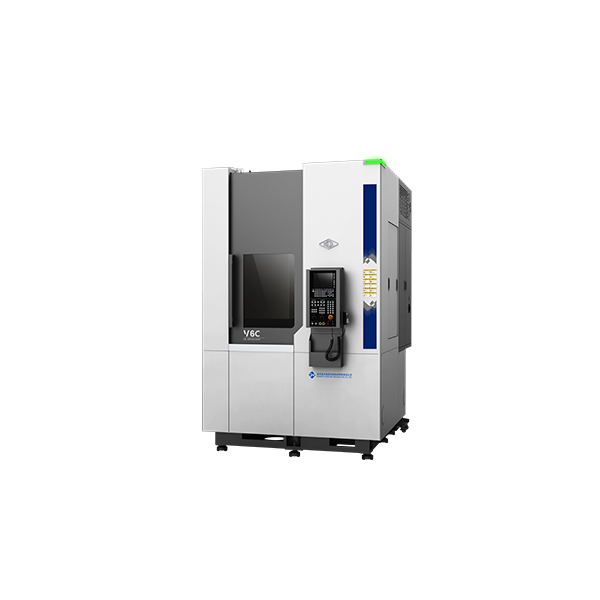

SHENYANG(SYMG) CNC vertical lathe V6C

|

Item |

Unit |

V6C |

| Processing capacity | ||

|

Max Swing Diameter |

mm |

Φ860 |

|

Max Cutting Height |

mm |

700 |

|

Max Turning Diameter |

mm |

Φ800 |

| Spindle | ||

|

Spindle Nose |

- |

A2-11 |

|

Speed |

r/min |

50-1500 |

|

Power |

kW |

22/30 |

|

Max output torque |

Nm |

1245 |

|

Chuck Diameter |

inch |

21″ |

| Feeding | ||

|

X-axis Max Travel Speed |

m/min |

16 |

|

Z-axis Max Travel Speed |

m/min |

16 |

| Travel | ||

|

X-axis Travel |

mm |

440 |

|

Z-axis Travel |

mm |

720 |

| Turret | ||

|

Turret type |

- |

Horizontal 8-Station |

|

Size of tool |

mm |

32×32/Φ50 |

| Accuracy | ||

|

Processing Accuracy |

- |

IT6-IT7 |

|

Surface Roughness of Finish Turning Outer Circle |

μm |

Ral.6 |

| Positioning accuracy | ||

|

X-axis |

- |

0.008 |

|

Z-axis |

mm |

0.010 |

| Repeat positioning accuracy | ||

|

X-axis |

mm |

0.006 |

|

Z-axis |

mm |

0.006 |

| Max Loading | ||

|

Disc |

kg |

600 |

| Machine Weight | ||

|

Main machine |

kg |

10500 |

| Machine size | ||

|

L×W×H |

mm |

2700×2200×3300 |

The V6 series CNC vertical lathe is a precision machining equipment designed for high-efficiency and high-precision production. This lathe features an excellent box structure that provides superior vibration absorption performance. Its sturdy construction ensures that the workpieces are stable throughout the machining process, resulting in high accuracy and surface quality of the finished product.

In addition, the V6 series CNC vertical lathe provides a large processing space and is suitable for processing automotive parts such as brake hubs, hubs, reducer shells, as well as elevator wheels, engineering sprockets, valves, and motor shells, among other products. With enhanced software and hardware capabilities, this lathe can perform standard hard turning and soft turning, as well as customized turning of special surfaces or shapes as required.

The versatility of the V6 series CNC vertical lathe is further enhanced by its support for the use of various special fixtures. This feature enables the lathe to process complex shell parts and shaped parts, further enhancing its machining capabilities and production efficiency.

Moreover, the V6 series CNC vertical lathe features a unique capability that allows it to be used for both soft turning and hard turning processing. This capability enables precision turning to be achieved, making it possible to replace the traditional grinding process and enabling cost savings. The replacement of the grinding process also reduces the generation of dust, wastewater, and other pollutants, resulting in a cleaner and safer working environment.

Overall, the V6 series CNC vertical lathe is a highly efficient, precise, and reliable machining equipment that can be used for a variety of manufacturing applications. It is particularly well-suited to the automotive and mechanical industries, where high accuracy, quality, and consistency are of utmost importance.