Industry News

-

How to improve the machining accuracy of slant-bed CNC lathe?

The slant-bed CNC lathe is a highly efficient and versatile machine tool that has revolutionized the way we approach mass production of machined parts. With its high-speed, high-precision, and high-rigidity capabilities, the slant-bed CNC lathe has become a staple of modern manufacturing, enablin...Read more -

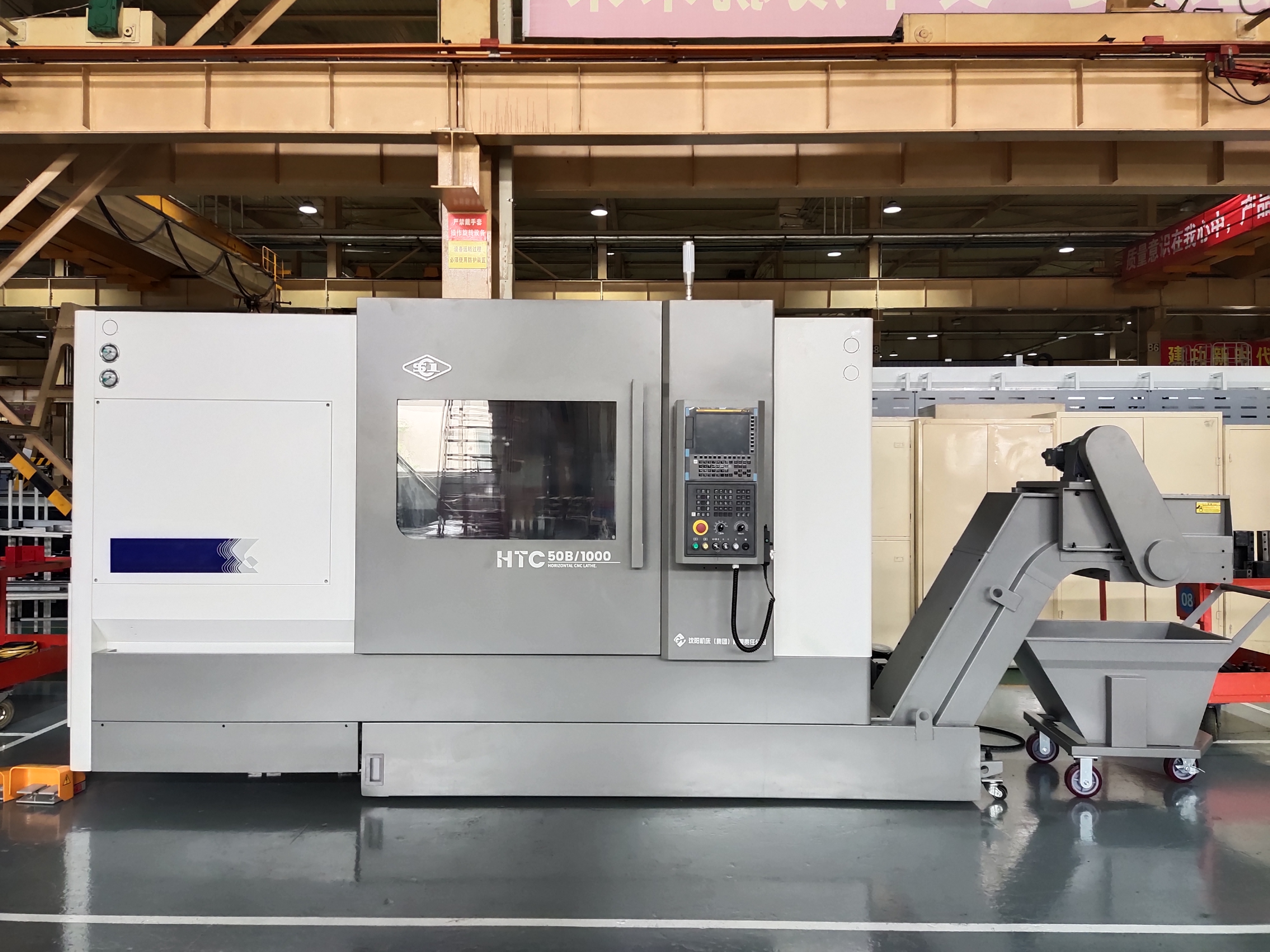

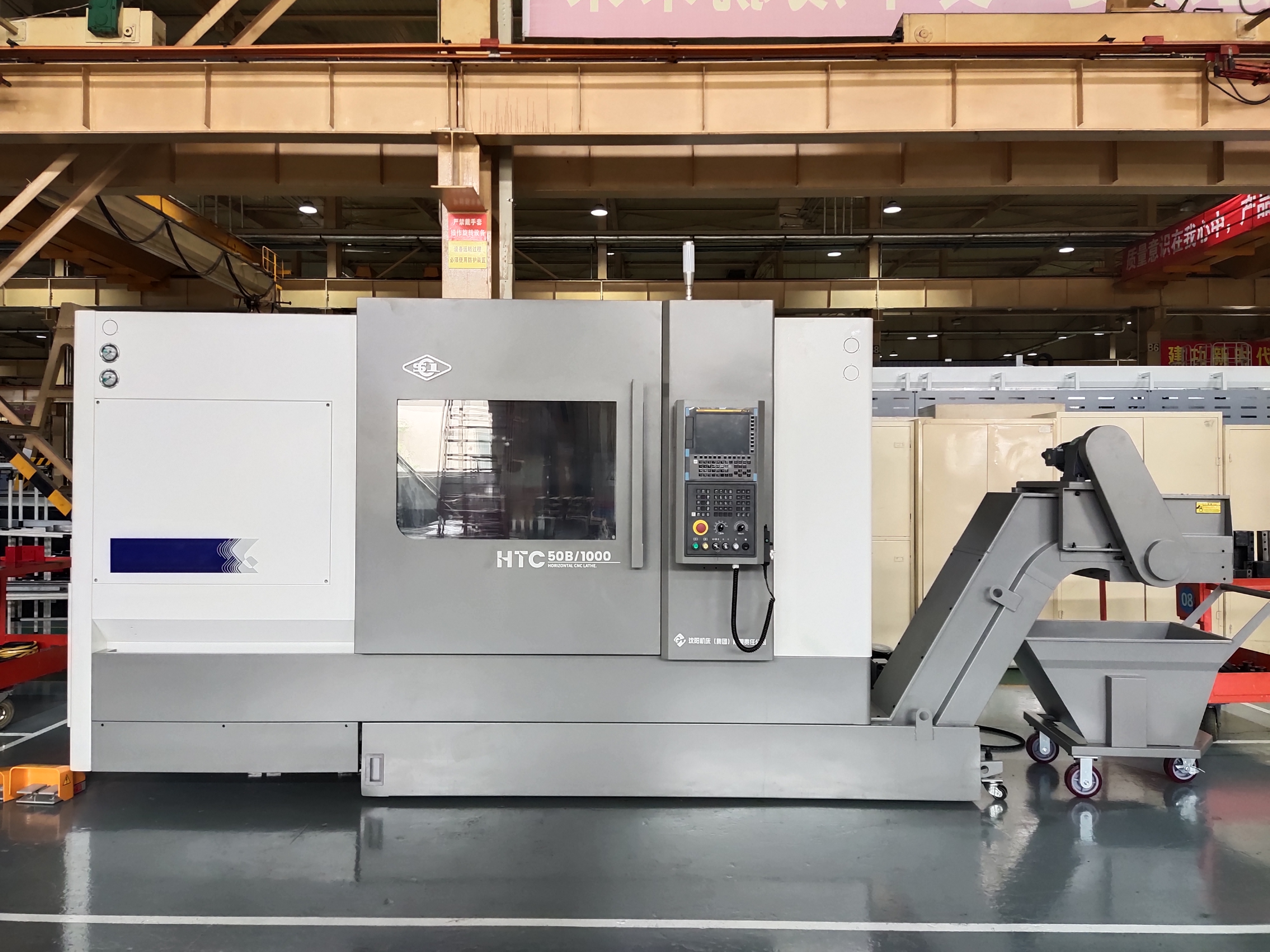

What are the structural characteristics and performance requirements of CNC machine tool equipment?

Although the CNC machine tools also have the bed and column, guide rail, operating table, tool holder and other components of ordinary machine tools. But in order to and control system of high precision, high speed control compared to the host part of the machine tool structure design also put fo...Read more -

The Benefits of Heavy Duty Horizontal Lathes in Modern Manufacturing

Heavy duty horizontal lathes have become a staple of modern manufacturing, delivering greater efficiency, accuracy, and versatility. These advanced machines are capable of handling large workpieces and performing a wide range of machining operations with high precision and speed. In this article,...Read more -

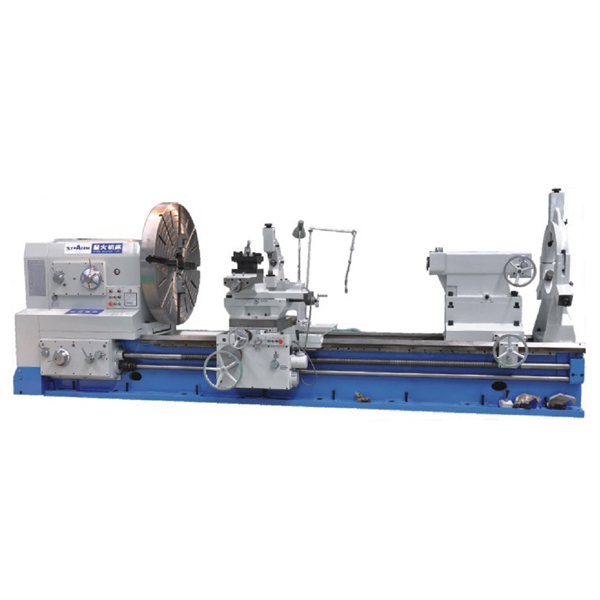

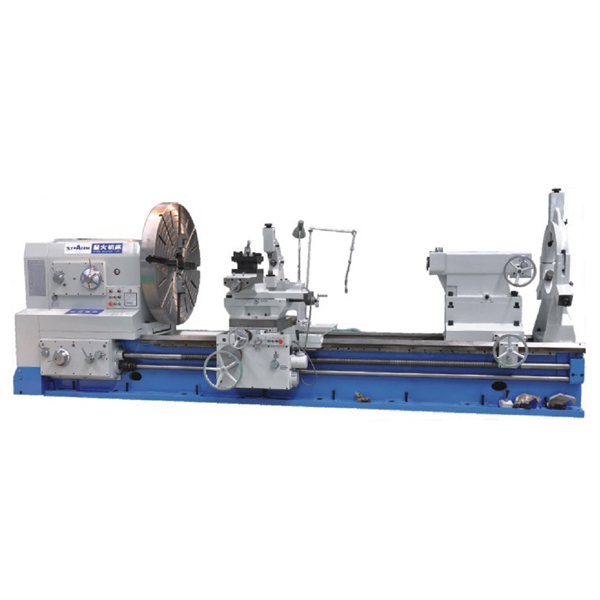

Conditions of use of conventional lathes.

Conventional lathe is one of the widely used lathes, accounting for about 65% of the total number of lathes, and it is called horizontal lathe because its spindle is placed horizontally. The main components of conventional lathe are spindle box, feed box, skid box, tool holder, tailstock, light b...Read more -

What to do if there is a power failure on the CNC pipe threading lathe

CNC pipe threading lathe, is a kind of horizontal lathe designed for turning and processing of large-diameter pipe fittings, featuring a large spindle through-hole aperture (generally 135mm or more) and chucks at the front and rear of the spindle box, so as to facilitate the clamping and processi...Read more -

How Slant Bed Turning Lathes Are Revolutionizing Precision Manufacturing

The manufacturing industry is constantly evolving, and one of the latest innovations making waves is the slant bed turning lathe. This advanced machine offers numerous advantages over traditional lathes, including greater stability, versatility, and precision. In this article, we’ll take a ...Read more -

Advantages of CNC slant bed lathes

In recent manufacturing news, the advantages of CNC slant bed lathes have been highlighted as a game-changer for the industry. These advanced machines offer numerous benefits that make them a top choice for precision machining operations. First and foremost, the CNC slant bed lathe design allows...Read more -

Advantages of Conventional Lathe

Conventional lathe processing range is very wide, can be rough and fine turning. It can process most parts of various nonferrous metals, ferrous metals and composite materials. The surface roughness of the workpiece is less than ra0.8 because of the higher cutting speed and the smaller feed. Conv...Read more -

Advantages of CNC vertical lathe

CNC vertical lathe adopts the latest microprocessor technology and fieldbus technology, its control system has powerful function, good man-machine interface and operation mode, high processing efficiency. The CNC vertical lathe has the advantages of high machining efficiency, low labor intensity,...Read more -

What is your opinion when it comes to the performance of slant-bed CNC lathes?

The slant bed type is a very versatile product type, which is relatively easy and simple to apply. But if we want to put it to good use, then we need to know what its performance and functions are. Slant bed CNC lathe is a very common type of machine tool in the machine tool industry, mainly used...Read more -

Did you know about the conditions of use of conventional lathes?

The normal use of the conventional lathe must meet the following conditions: the power supply voltage fluctuation at the location of the machine tool is small, the ambient temperature is less than 30 degrees and the relative humidity is less than 80%. The location of the machine should be far awa...Read more -

Loading and unloading of conventional lathe chucks and their jaws, come in and see!

The chuck is a common accessory of common lathe, which is used to clamp the workpiece. There are two kinds of chucks commonly used on lathes: three-jaw self-centering chucks and four-jaw single-action chucks. The three jaws of the three-jaw self-centering chuck are evenly distributed around the c...Read more