China Top Machinetools

News

-

The Timeless Reliability of Conventional Lathes: A Comprehensive Guide

Introduction: Conventional lathes have stood the test of time and continue to be an indispensable tool in the machining industry. With their ability to shape and transform raw materials into precise components, conventional lathes have earned a reputation for their timeless reliability. In this c...Read more -

Key Features of CNC Slant Bed Lathes

Introduction: CNC Slant bed lathes are an integral part of modern manufacturing processes, renowned for their unique working bed structure and exceptional machining capabilities. These advanced machines offer numerous benefits that make them highly sought after across various industries. In this ...Read more -

Basic Components of a Machining Centre

Various types of machining centres, although the shape of the structure is different, but from the overall view of the main components of the following parts. I. Basic parts By the bed, column and table and other large parts, is the basic components of the machining centre, they can be cas...Read more -

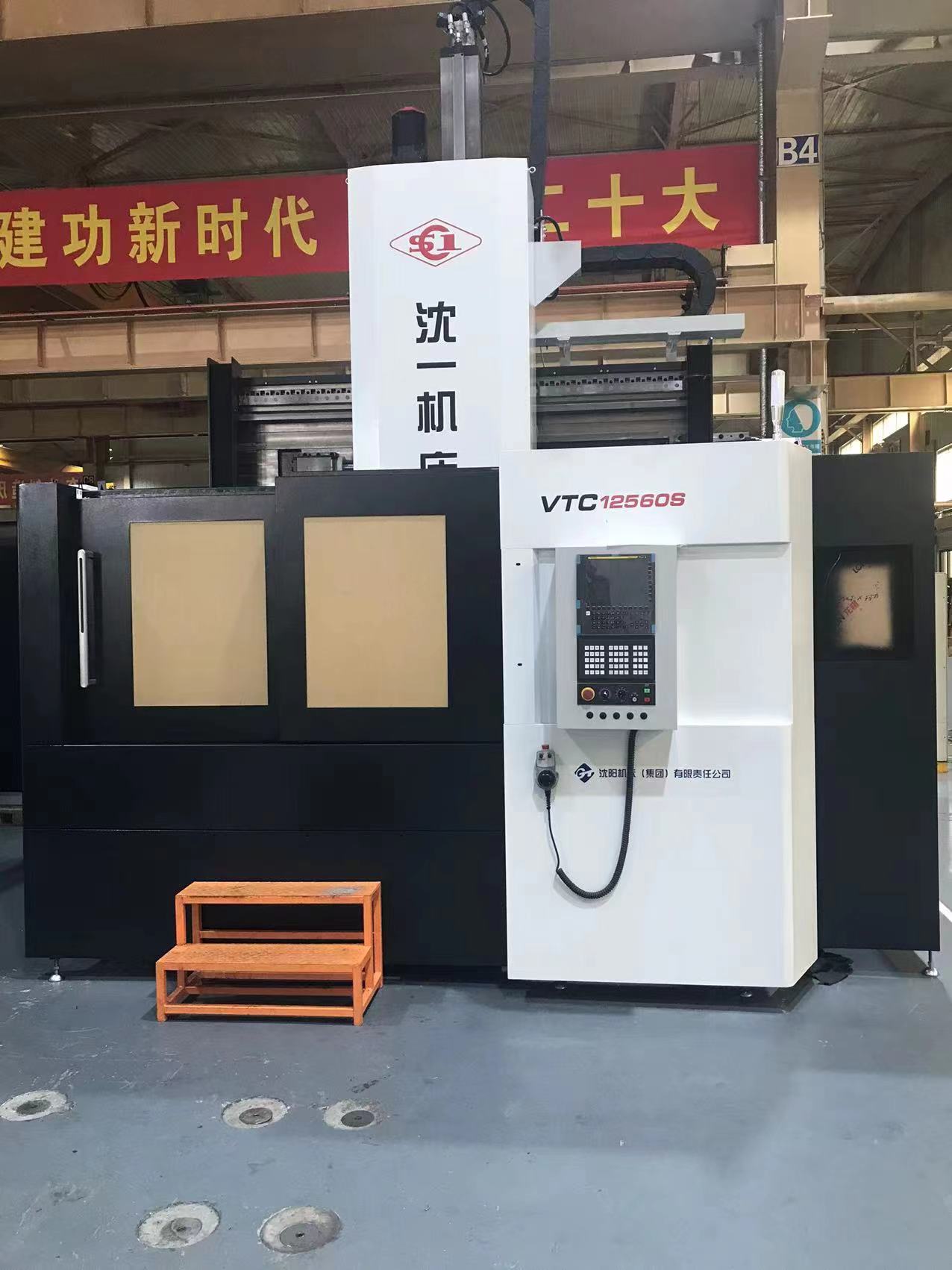

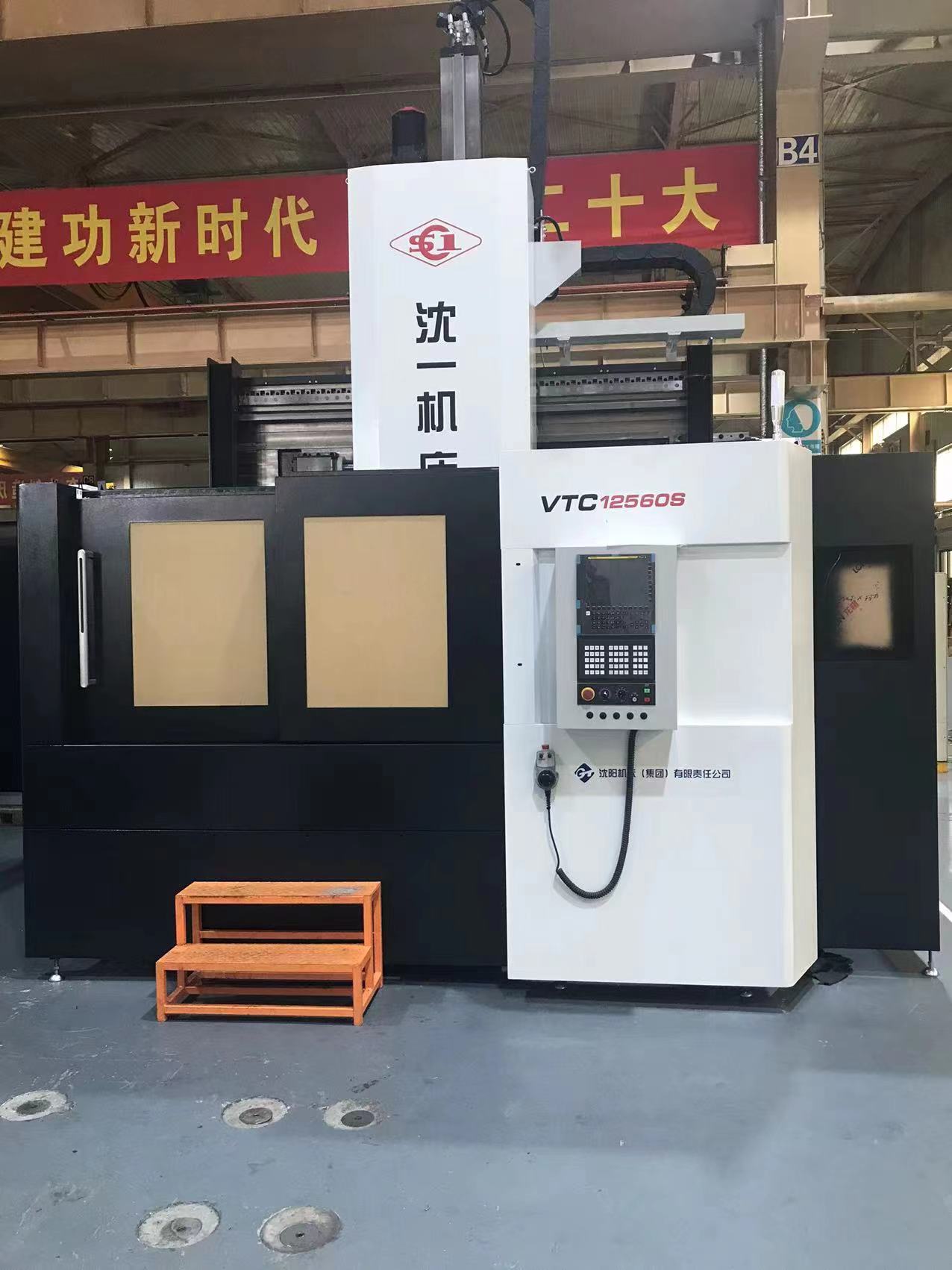

Shenyang vertical CNC lathe with high-precision machining capability

Shenyang vertical CNC lathe adopts servo motor to drive the spindle and feed axis, and controls the tool movement trajectory and machining process through the CNC system. Shenyang vertical CNC lathe’s spindle speed is adjustable and feed speed is controllable, which can realise machining tasks of...Read more -

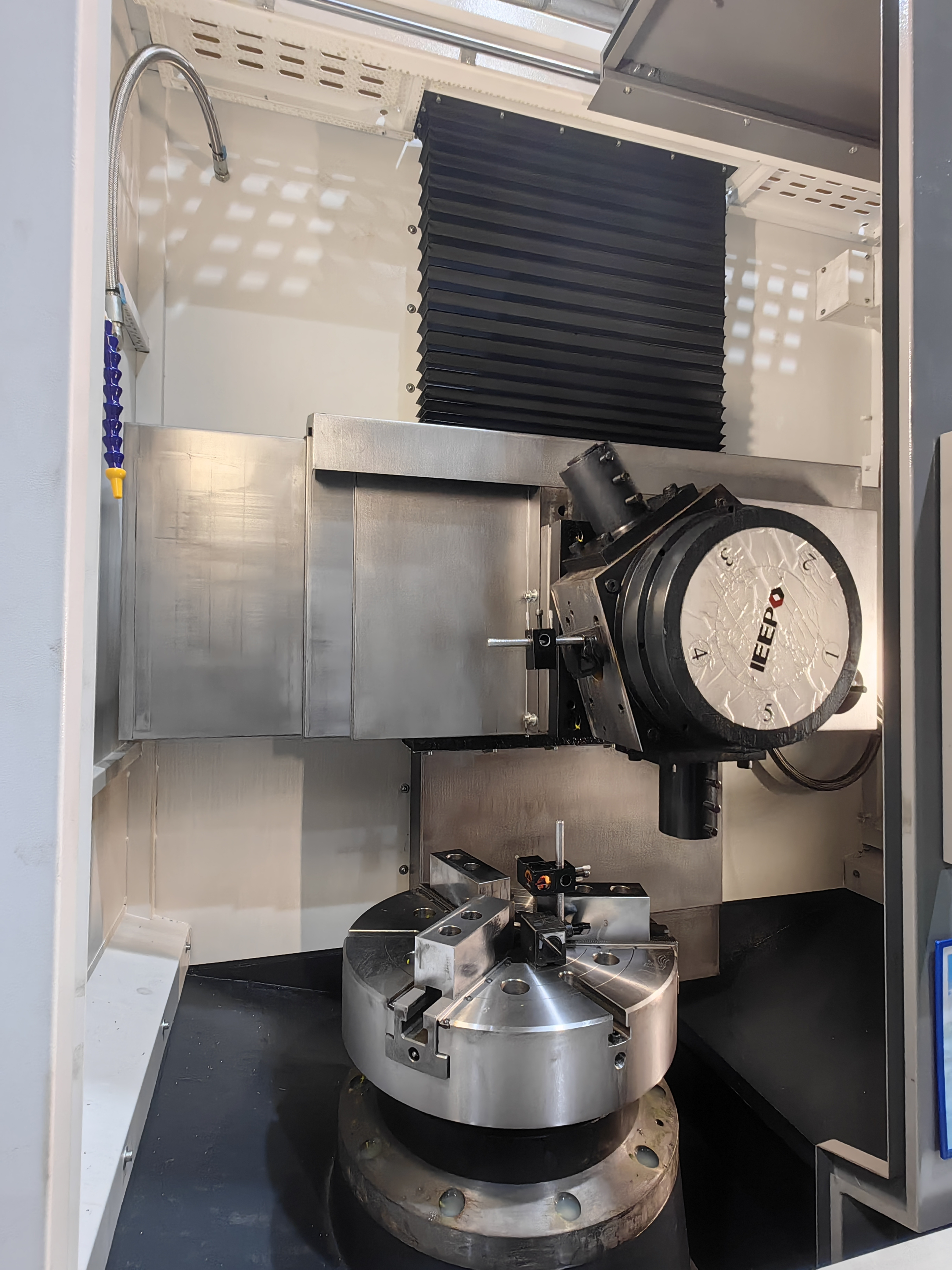

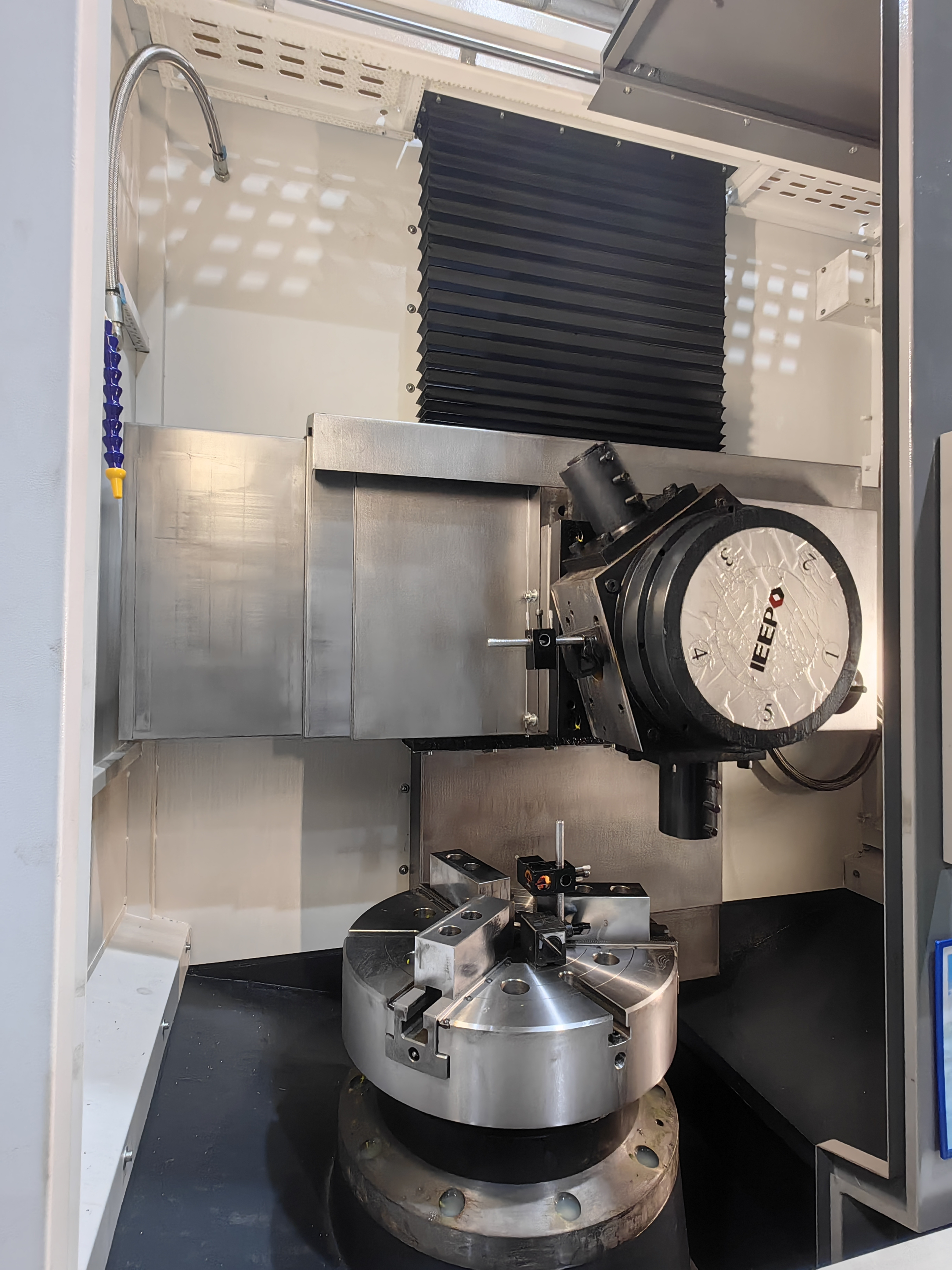

What are the common failures of 5-axis linkage machining centres?

5-axis linkage machining centre is a kind of high-precision and high-efficiency CNC machining equipment, which is widely used in mould making, aerospace, automotive parts and other industries. However, due to long time operation, wear and tear and improper use, 5-axis linkage machining centre wil...Read more -

Horizontal machining centers should pay attention to what maintenance, can extend the life?

Horizontal machining centers are an important type of CNC machine tool equipment that is widely used in the machining and manufacturing of parts and components. In order to guarantee the normal operation of horizontal machining centers and extend their service life, proper maintenance measures ar...Read more -

The use of CNC vertical machining centres must meet which four conditions

Introduction: When using CNC vertical machining centers, it is important to ensure that certain conditions are met to maximize their performance, accuracy, and reliability. In this article, we will discuss the four key conditions that must be considered when utilizing CNC vertical machining cente...Read more -

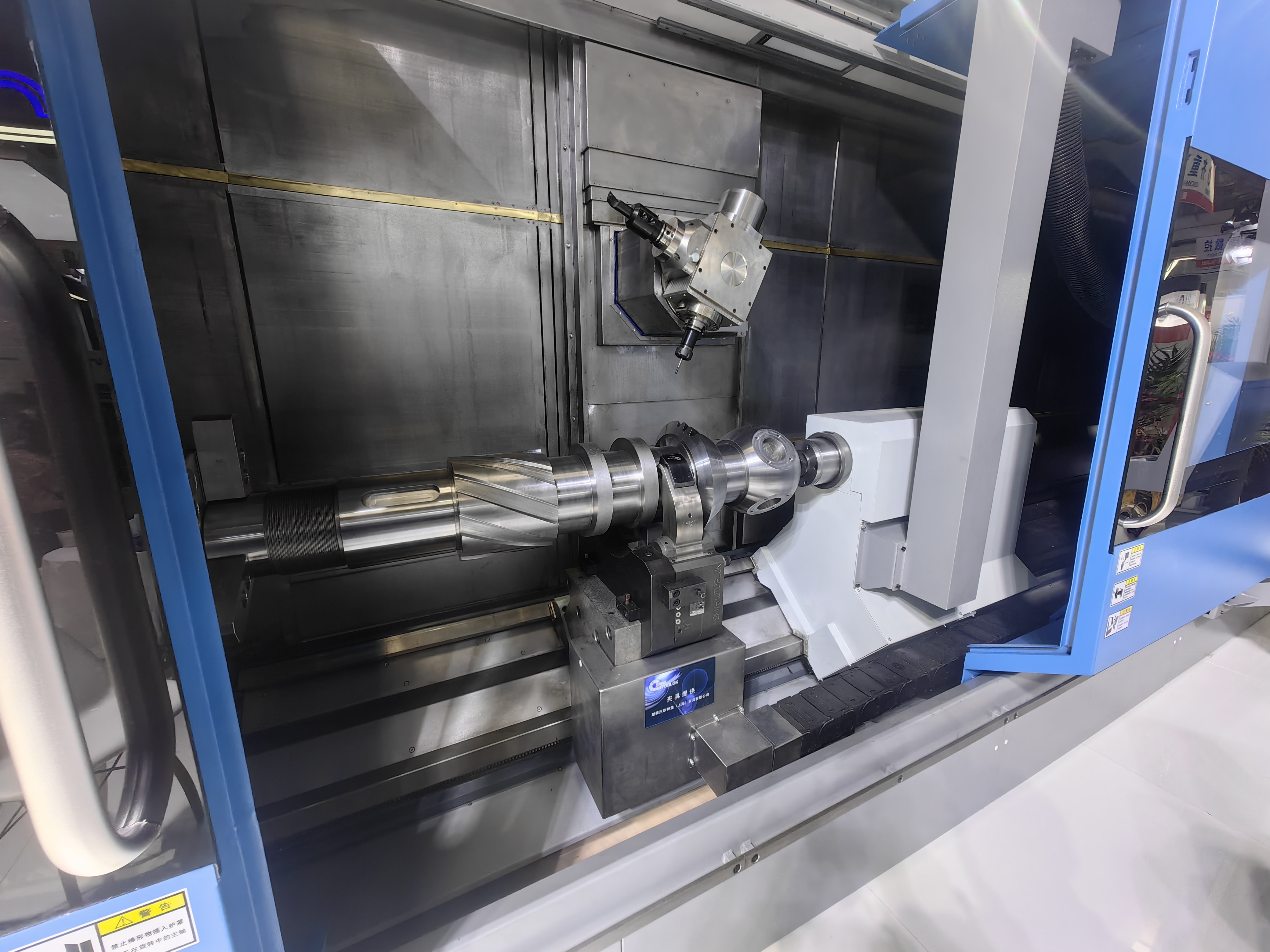

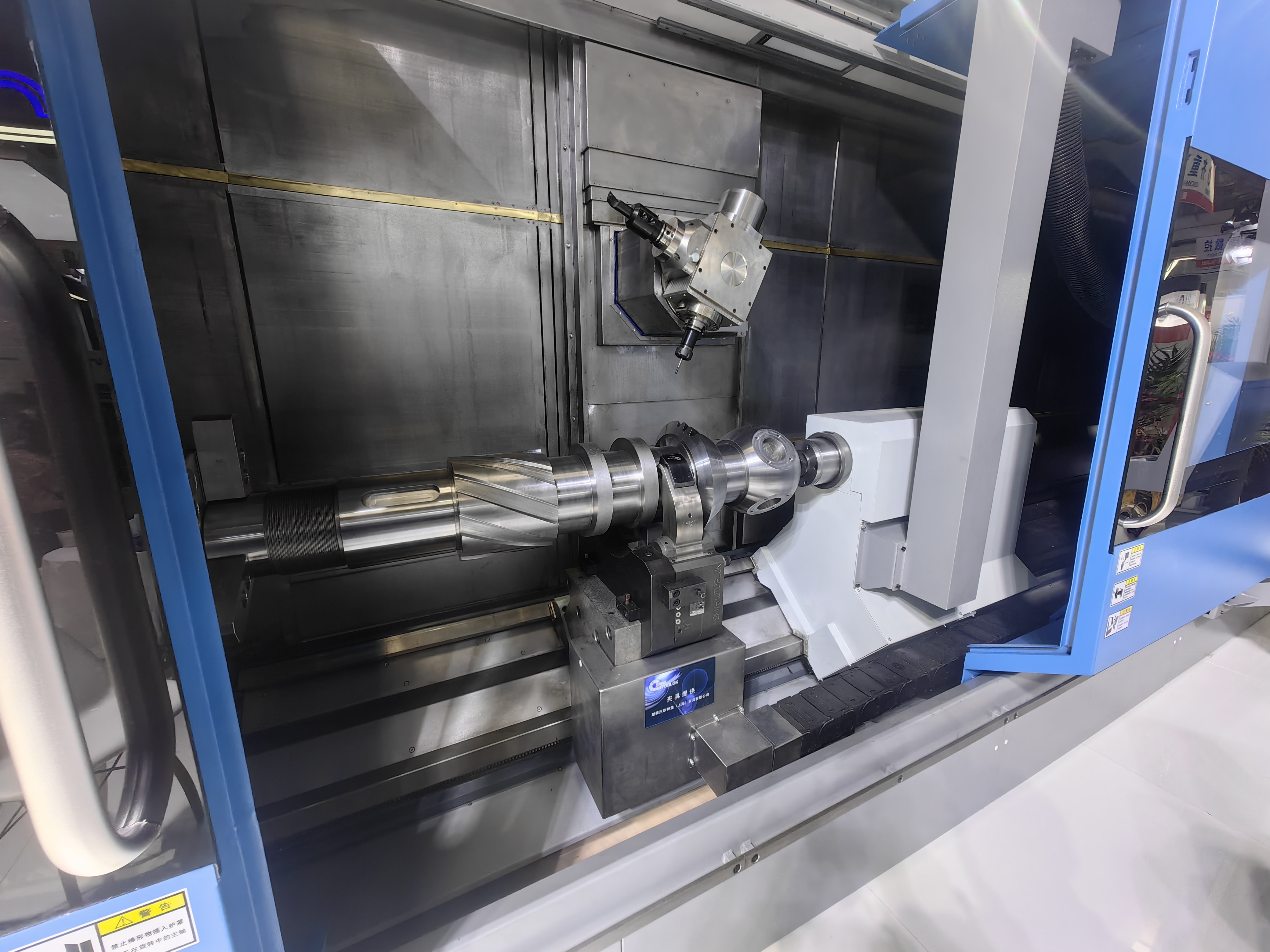

Why do so many people choose CNC Mill-Turning machines?

CNC mill-turning machine is a high-precision machining equipment that integrates milling and turning functions.In recent years, this kind of machine tool is favored by more and more enterprises in the manufacturing field, and there are many advantages behind its popularity. This article will expl...Read more -

Commonly used slant bed CNC lathe maintenance methods you know?

Maintenance of CNC equipment, especially slant bed CNC lathes, is a complex and highly technical task, as CNC equipment differs significantly from ordinary equipment. In this article, we will discuss some commonly used maintenance methods for slant bed CNC lathes to ensure their optimal performan...Read more -

In which industries are five-axis, five-linkage machining centres widely used?

The five-axis five-linkage machining centre is a highly precise and efficient piece of machinery that is widely used in various industries. five-linkage machining centre possesses the ability to process complex parts with high accuracy, which makes it a valuable asset in many industries. The foll...Read more -

What does the maintenance of vertical lathe include

Vertical lathes are commonly used in the manufacturing industry for various applications, especially when producing specialized parts. These lathes offer superior performance in many aspects. However, in order to further improve their service life, it is essential to pay attention to maintenance ...Read more -

CNC machine tools for processing the route and process sequence to determine

The toolpath is the path of the CNC machine tool relative to the workpiece throughout the machining process, which not only includes the content of the work step, but also reflects the sequence of the process. The tool path is also one of the main bases for programming. Therefore, CNC machine too...Read more