YUNNAN Manual Lathe – YUNNAN Vertical Machining Center V6 V8 V85 V10 – Maiouke

YUNNAN Manual Lathe – YUNNAN Vertical Machining Center V6 V8 V85 V10 – Maiouke Detail:

YUNNAN Vertical machining centers V6 V8 V85 V10

| Item | Unit | V6 | V8 | V85 | V10 | ||

| Table Size | Length×Width | mm | 700×420 | 1000×500 | 1000×550 | 1300×600 | |

| Maximum loading weight | kg | 400 | 600 | 800 | 800 | ||

| T-slot date ×Width ×Dis. between centers | mm | 3-18×125 | 5-18×102 | 5-18×100 | 5-18×100 | ||

| Spindle | Taper/dia. | - | BT40/Φ140 | BT40/Φ150 | BT40/Φ150 | BT40/Φ120 | |

| Speed | Rpm | 12000 direct motor | 12000 direct motor | 10000 | 12000 direct motor | ||

| Main motor | Power | Kw | 5.5 | 7.5 | 7.5 | 7.5 | |

| Travel | XYZ travel | mm | 600/400/420 | 800/500/500 | 800/550/550 | 1000/600/600 | |

| Dis. from spindle to table | mm | 170~590 | 170~670 | 140~690 | 170~770 | ||

| XYZ rapid speed | m/min | 48/48/48 | 48/48/48 | 48/48/48 | 36/36/24 | ||

| Dimension size | Length×Width×Height | mm | 2100x1675x2300 | 2630x2050x2350 | 2500x2300x2700 | 3260x2350x2600 | |

| Gross weight | kg | 4100 | 4500 | 5500 | 7200 | ||

| Position accuracy | mm | 0.012/0.010/0.010 | 0.015/0.010/0.010 | 0.015/0.010/0.010 | 0.016/0.012/0.012 | ||

| JISB 6330 ±0.005/300 | JISB 6330 ±0.006/300 | ||||||

| Repeat position accuracy | mm | 0.006/0.004/0.004 | 0.006/0.004/0.006 | 0.006/0.004/0.006 | 0.007/0.006//0.006 | ||

| JISB 6330 ±0.003 | |||||||

Characteristic

•The tool magazine support and column are cast in one piece, which eliminates the influence of the tool magazine on the vertical accuracy and improves the accuracy retention of the machine tool

•The table is optimized in gateway structure, and the thickness is thickened to 130mm, which improves the rigidity and accuracy retention

•The sliding saddle adopts multi-layer gateway structure, which improves the rigidity, compression resistance and bending resistance

•The oversized widened base improves the stability of the machine tool. Equipped with large-scale circular water tank, it can be equipped with spiral chip conveyor, which can greatly prevent the leakage of chip liquid

•Z-axis adopts large torque motor for fast response

•The main shaft adopts a short nose structure, and the speed reaches 10000rpm. The continuous processing does not need to be equipped with an oil cooler, which reduces the user’s use cost and reduces the equipment failure rate.

•The three axis are equipped with 4016 imported ball screws, with a fast moving speed of 48m/min, which effectively improves the processing efficiency. Large stroke 800*550*550mm with large linear guiideway

The three axes are equipped with imported roller guideway of 35/45/45 specifications, and the Z axis adopts the design of double-sided six slide blocks to increase the bearing capacity of the machine tool and chip rigidity.

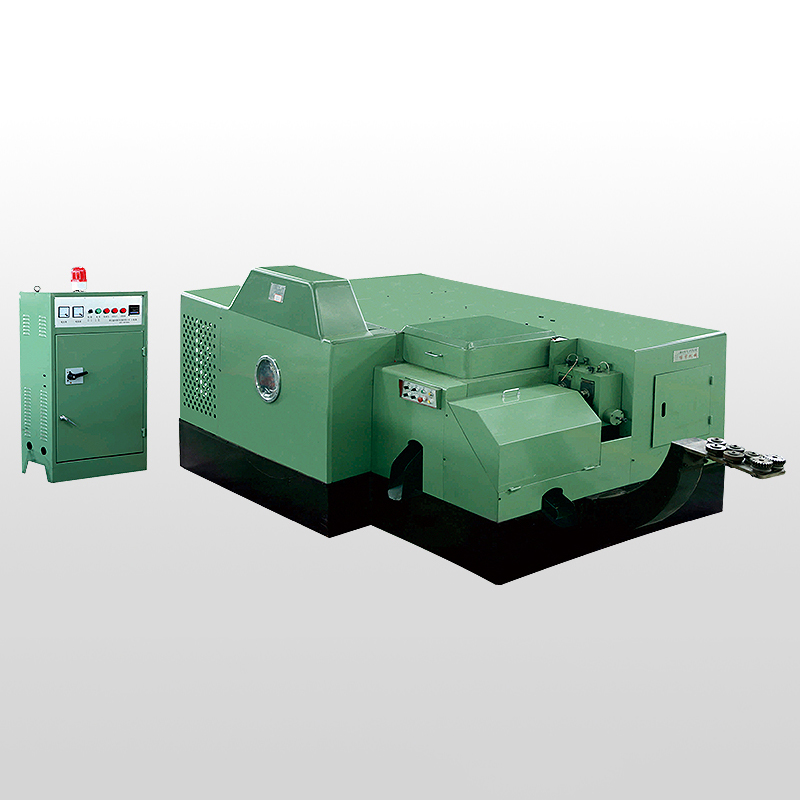

Product detail pictures:

Related Product Guide:

We've got a really efficient group to deal with inquiries from prospects. Our purpose is "100% customer fulfillment by our product excellent, price & our group service" and enjoy a superb track record amid clientele. With many factories, we can easily deliver a wide selection of YUNNAN Manual Lathe – YUNNAN Vertical Machining Center V6 V8 V85 V10 – Maiouke , The product will supply to all over the world, such as: Croatia, Zurich, Lithuania, If you are interested in any of our products and solutions or would like to discuss a custom order, remember to feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.