Worm Milling Machine Manufacturers – SHENYANG(SYMG) Boring machine PBC 110(f)m PBC130m PBC 110(f) PBC130(f) – Maiouke

Worm Milling Machine Manufacturers – SHENYANG(SYMG) Boring machine PBC 110(f)m PBC130m PBC 110(f) PBC130(f) – Maiouke Detail:

Specification

|

Item |

Unit |

PBC110(f)m |

PBC 130m |

PBC 110(f) |

PBC 130(f) |

|

|

Table Size |

mm |

1000×1250 |

1600×1800 |

1250×1400 |

1600×1800/ |

|

|

Max. Loading of Table |

T |

5 |

10 |

8 |

15 |

|

|

Diameter of Spindle |

mm |

Φ110 |

Φ130 |

Φ110 |

Φ130 |

|

|

Diameter of Faceplate |

mm |

- Φ630 |

- |

- Φ630 |

- Φ730 |

|

|

Spindle Taper Bore |

- |

ISO 7:24 NO.50 |

ISO 7:24 NO.50 |

ISO 7:24 NO.50 |

ISO 7:24 NO.50 |

|

|

Turret |

- |

JT50/BT50 |

JT50/BT50 |

JT50/BT50 |

JT50/BT50 |

|

|

Spindle Speed |

r/min |

10-2500 10-2000(fm) |

10-3000 |

10-3000 10-2000(f) |

10-3000 10-2000(f) |

|

|

Faceplate Speed |

r/min |

- 10-200 |

- |

- 10-200 |

- 10-125 |

|

|

Main Motor Power |

kW |

17/20.4 |

25/30 |

19.5/23.4 |

25/30 |

|

|

Max. Torque of Spindle |

Nm |

1300/1600 |

2100/2600 |

1100/1300 |

2100/2600 2200/2600(f) |

|

|

table Travel–X |

mm |

2000 |

2000/3000/4000 |

2000/3000 |

2000/3000/4000 |

|

|

Headstock Travel–Y |

mm |

1500 |

1600/2000 |

1500/2000 |

1600/2000/2500 |

|

|

Column travel Z |

mm |

1200 |

1600/2000 |

1200/2000 |

1600/2000 |

|

|

Spindle travel–W |

mm |

550 |

800 |

550 |

800 |

|

|

Faceplate slider travel U |

mm |

- 140 |

- |

- 140 |

- 200 |

|

|

Swing over Table B |

o |

0.001×360 |

0.001×360 |

0.001×360 |

0.001×360 |

|

|

Distance from spindle center to table surface |

mm |

60-1560/30-1530 |

100-1700 |

60-1560 |

100-1700 |

|

|

Distance from spindle end face to table center |

mm |

350 487(fm) |

850 |

350 487(f) |

850 |

|

|

Feeding speed |

X、Y、Z |

mm/min |

1-6000 |

X/Z:l-12000,Y:l-10000 |

1-8000 |

1-8000 |

|

|

W |

mm/min |

1-2000 |

1-3000 |

1-2400 |

1-3000 |

|

|

U |

mm/min |

- 1-1000 |

- |

- 1-2400 |

-1 -3000 |

|

|

B |

r/min |

0-1 |

0-1.5 |

0-1.5 |

0-1.5 |

|

Rapid feed speed |

X、Y、Z |

m/min |

9 |

X/Z:12,Y:10 |

15 |

12 |

|

|

W |

m/min |

2.4 |

3 |

2.4 |

3 |

|

|

U |

m/min |

- 2.4 |

- |

- 2.4 |

- 3 |

|

|

B |

r/min |

2 |

1.5 |

1.5 |

1.5 |

|

Positioning accuracy |

X、Y、Z |

mm |

X:0.02/0.016(Grating) |

XZ:0.015/0.01(Grating) |

XZ:0.015/0.01(Grating) |

XZ:0.015/0.01(Grating) |

|

|

W |

mm |

0.02 |

0.012 |

0.012 |

0.012 |

|

|

U |

mm |

- 0.032 |

- |

- 0.032 |

- 0.032 |

|

|

B |

“ |

12/10 (Grating),4X90°:6 |

8 (Grating),4X90°:6 |

6 |

6 |

|

Repeatability accuracy |

X、Y、Z |

mm |

X:0.011 YZ:0.01 |

0.008 |

0.008 |

0.008 |

|

|

W |

- |

0.016 |

0.01 |

0.01 |

0.01 |

|

|

U |

mm |

- 0.018 |

- |

- 0.018 |

- 0.018 |

|

|

B |

“ |

7 |

6 |

4 |

4 |

|

CNC system |

- |

SIEMENS 828D |

SIEMENS 828D |

SIEMENS 828D |

SIEMENS 828D |

|

Characteristic:

The machine is in the form of a T-shaped layout, with a single column and a side-hung box structure. The table and slide move along the cross-bed guide (X-axis coordinate), and the column is fixed to the The column is fixed to the slide. The table and slide move along the horizontal bed guide (X-axis coordinate), the column is fixed on the slide. The spindle box moves vertically along the column guide (Y axis coordinate), the CNC table rotates 360° (B axis), the spindle (boring axis) moves within the milling axis (W axis coordinate).

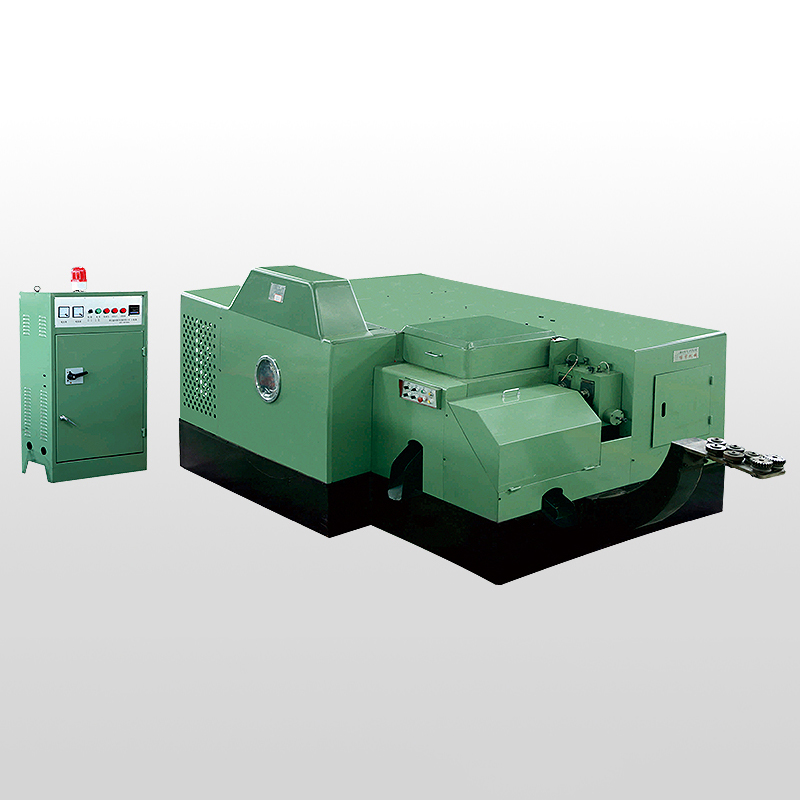

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority from the crucial certifications of its market for Worm Milling Machine Manufacturers – SHENYANG(SYMG) Boring machine PBC 110(f)m PBC130m PBC 110(f) PBC130(f) – Maiouke , The product will supply to all over the world, such as: Japan, Turkey, Grenada, Our staffs are rich in experience and trained strictly, with qualified knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we'll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

A good manufacturers, we have cooperated twice, good quality and good service attitude.