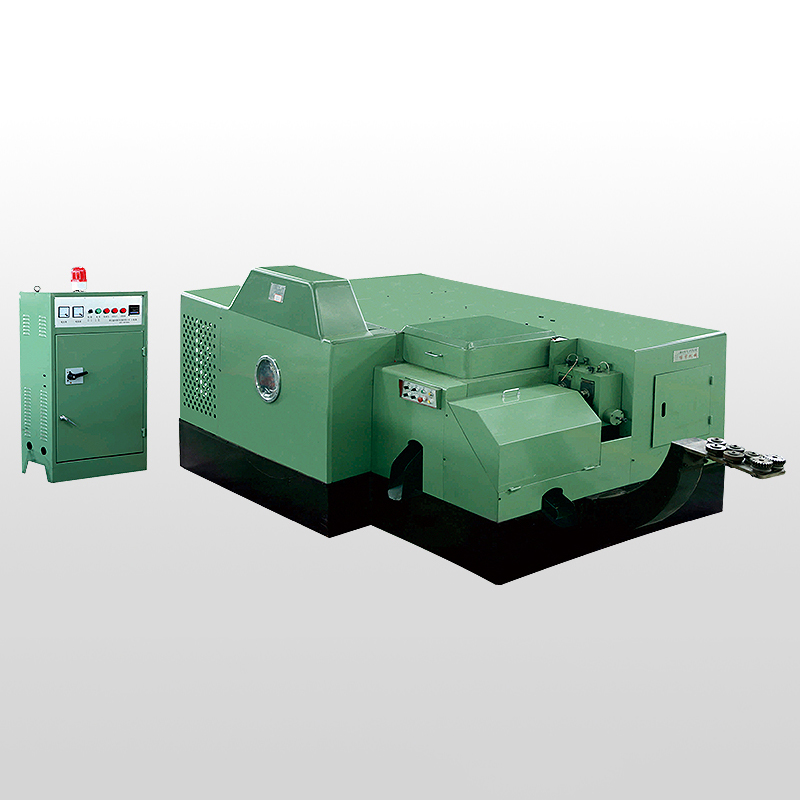

China cnc worm hobbing machine Manufacturers – XINYUE Double-Sided CNC Lathe SC32-300 SC72-400 SC130-400 – Maiouke

China cnc worm hobbing machine Manufacturers – XINYUE Double-Sided CNC Lathe SC32-300 SC72-400 SC130-400 – Maiouke Detail:

Specification

|

Technical Parameter |

Unit |

SC32-300 |

SC72-400 |

SC130-400 |

|

Maximum clamping diameter |

mm |

32 |

72 |

130 |

|

Maximum machining length |

mm |

300 |

400 |

400 |

|

Minimum processing length |

mm |

100 |

200 |

200 |

|

Maximum spindle speed |

R/min |

3500 |

2000 |

1200 |

|

Spindle motor power |

kw |

5.5 |

5.5 |

7.5 |

|

Z axis fast travel |

m/min |

16 |

16 |

16 |

|

X axis fast travel |

m/min |

16 |

16 |

16 |

|

Z axis max. guide travel |

mm |

400 |

400 |

400 |

|

X axis max. guide travel |

mm |

300 |

300 |

300 |

|

Machine weight |

kg |

4000 |

4000 |

4500 |

|

Machine Dimension |

mm |

2800×2080×1695 |

2800×2080×1695 |

2800×2080×1695 |

|

Please note: The maximum processing length is customized according to customer requirements. |

||||

Characteristic

The double sided turning machine with centered spindle, two Z-axises, two X-axises and two-way moving pallets has characteristics of high precision, high efficiency, high rigidity, etc.

1. Processing is carried out on both ends of the rotating workpiece, which can achieve high concentricity.

2. Double end processing doubles efficiency.

3. The simultaneously processed center holes, threads, inner holes, external circles end faces can have a concentricity ≤0.01.

4. Simultaneous processing of inner holes, female threads can be achieved for pipes and sleeve parts, with a concentricity ≤0.01.

5. Ramp rail layout, high rigidity, high precision are very conducive to chip removal.

6. Smart double channel system is simple for operation.

7. Imported linear guides and guide screws are used to guarantee precision and stability of the machine.

8. Hydraulic or pneumatic workpiece clamping mechanisms are provided for convenient clamping.

9. Automatic chip removal.

10. Automatic forced lubrication.

11. High clamping accuracy ≤0.015.

12. Flexible Fast Rubber Clamps

The rubber clamps are easy for handling.The machine adopts hydraulic or pneumatic clamping, which is fast, stable and safe.

13. Centered Spindle (Bidirectional Spindle)

Optional bearing and static pressure spindles can process on both sides with high effi ciency, high precision.

14. Optional Tool Turret

Flexible tool adaption solution that meets complex part processing.Inside turret water cool, which cools thoroughly.

15. Design Of Tool Arranging And Mounting

Design of tool arranging and mounting enables customers to use easily, which is cost-effective, stable and durable.

16. Inverted Vertical Structure, More Smooth Chip Removal

This machine adopts special double channel numerical control system with convenient programming and formidable functions.

Parts Machined By Roll Forming Machine

Product detail pictures:

Related Product Guide:

All we do is often involved with our tenet " Purchaser to start with, Rely on initially, devoting over the food stuff packaging and environmental defense for China cnc worm hobbing machine Manufacturers – XINYUE Double-Sided CNC Lathe SC32-300 SC72-400 SC130-400 – Maiouke , The product will supply to all over the world, such as: Peru, Lithuania, Thailand, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.