Spline Forming Machine Manufacturers – XINYUE Spline Roll Forming Machine CZL-16NCS 24NCS 36NCS CL-48NCS – Maiouke

Spline Forming Machine Manufacturers – XINYUE Spline Roll Forming Machine CZL-16NCS 24NCS 36NCS CL-48NCS – Maiouke Detail:

Specification

|

Technical Parameter |

Unit |

CZL-16NCS |

CZL-24NCS |

CZL-36NCS |

CL-48NCS |

|

Loaded Tool Length |

Inch |

16 |

24 |

36 |

48 |

|

Max. Module |

m |

1.0 |

1.25 |

1.75 |

2.0 |

|

Max. Teeth Diameter |

mm |

22 |

40 |

50 |

60 |

|

Workpiece Length |

mm |

800 |

800 |

800 |

800 |

|

Cylindricity |

mm |

0.01 |

0.015 |

0.015 |

0.02 |

|

Roughness |

μm |

0.4-1.6 |

0.4-1.6 |

0.4-1.6 |

0.4-1.6 |

|

Max. Roll Forming Length |

mm |

60 |

100 |

120 |

160 |

|

Roll Forming Capacity Factor |

mm |

35 |

50 |

70 |

160 |

|

Please note: The maximum processing length of workpiece can be customized / please consult us for processing capacity details. |

|||||

Characteristic

1. Circumferential Pitch Cumulative Adjustment

This innovation can easily compensate for tool symmetry deviation, which completely solves the problems that have to be handled through tedious mechanical or gasket adjustments. A better circumferential pitch cumulative accuracy can be achieved.

2. Optimized Synchronization Of Main Sliding Table

Nano-scale computing is adopted in control system, which makes synchronization performance better than gear synchronization or gear box synchronization.

3. Multi-stage CNC roll forming

Full CNC machine can complete multi-stage roll forming with different parameters on the same workpiece, which can be called the king of roll forming.

4. CNC motor drive, low energy consumption

Compared with hydraulic drive, CNC drive can save 70% of energy, which is in line with the development of the times. So it is really a low consumption and high efficiency equipment.

5. High performance, less procedure

Multi-stage processing technology reduces labor intensity and makes it possible for one person to operate multiple devices; it also reduces the flow of products, uses fewer procedures and reduces product conflicts.

6. Vertical structure

The main slide moves vertically and symmetrically, which is conducive to chip removal and workpiece cooling and greatly reduces the wear and tear of the guide rail; moreover, the compact vertical structure of the CNC drive greatly reduces the occupation of the ground.

7. Overall frame structure

The hexahedral frame support connection greatly enhances the overall rigidity of the machine body and improves the stability of the machine tool.

8. Humanized operation interface

The system can display fault information, processing count, timing, store program, detect the total length of the workpiece, anti-failure or empty clamping, self-learning, etc.

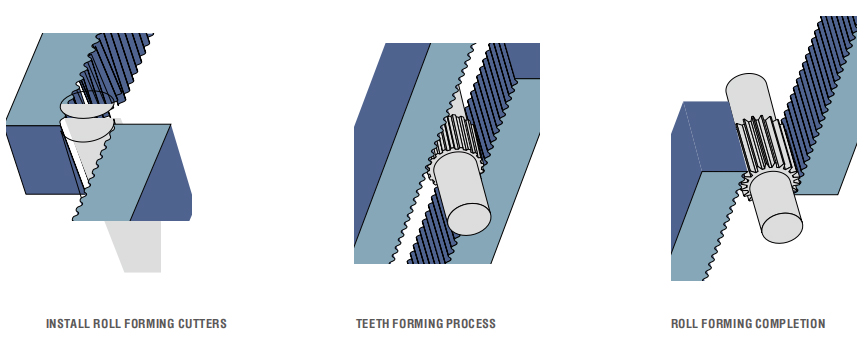

Parts Machined By Roll Forming Machine

Suitable for straight teeth and helical gear teeth on various shaft parts such as gearbox gear shaft, cage constant velocity universal joint, spline shaft, motor shaft, textile roller, spring torsion bar, steering gear, crankshaft, etc.

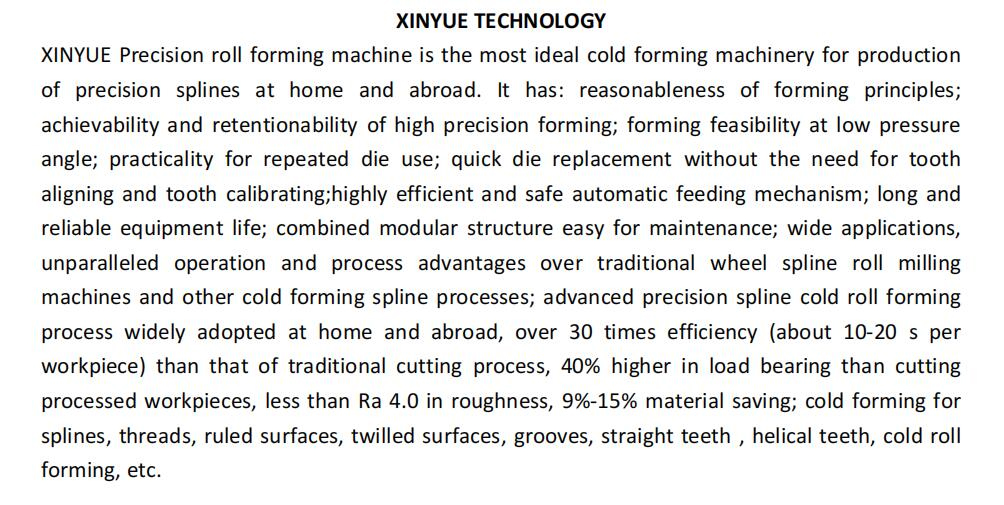

Roll forming machine roll forming process

Multi-stage roll forming process

Processing principles

The principles of cold-roll forming are that the roll forming cutter dies installed on the sliding table operate in opposite linear motion. The workpiece splines are formed by the increasing teeth amount of the roll forming cutters, and the final shaping precision and stability of the splines are obtained by the rigid distance between the two roll forming cutters. The opposite linear movements of the roll forming cutters are driven by hydraulic machine and the high synchronization of the two roll forming cutters is guaranteed by the racks and pinions. The synchronization of two roll forming cutters is guaranteed by the ball screws on the CNC machine. (Its synchronization accuracy is higher).

Product detail pictures:

Related Product Guide:

We emphasize progress and introduce new merchandise into the market each and every year for Spline Forming Machine Manufacturers – XINYUE Spline Roll Forming Machine CZL-16NCS 24NCS 36NCS CL-48NCS – Maiouke , The product will supply to all over the world, such as: Austria, Jersey, Honduras, By continuous innovation, we will present you with more valuable items and services, and also make a contribution for the development of the automobile industry at home and abroad. Both domestic and foreign merchants are strongly welcomed to join us to grow together.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.