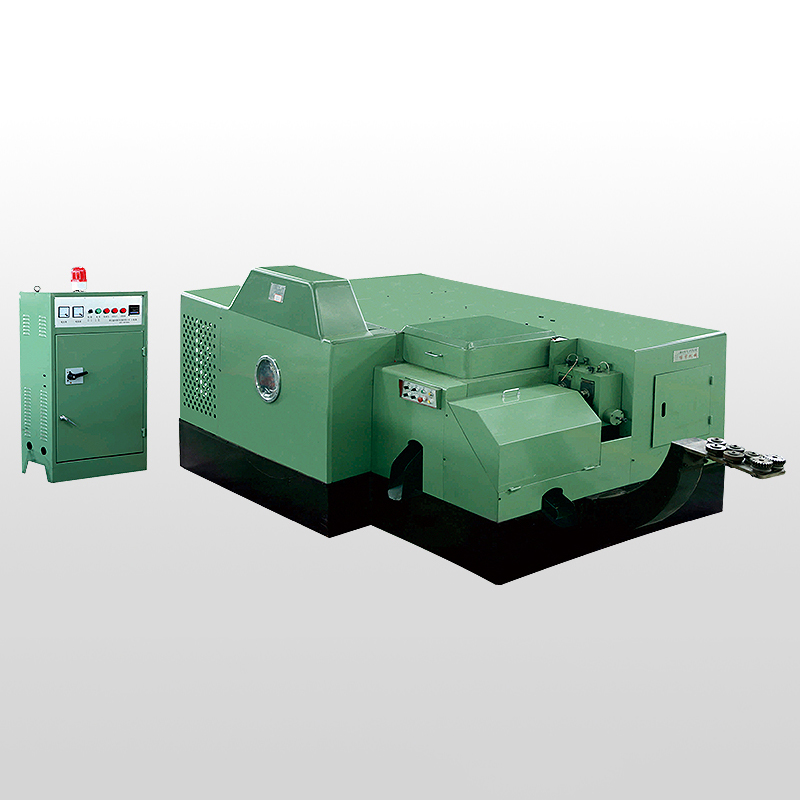

Slant Bed Lathe CY-K55 Manufacturers – YUNNAN Slant Bed Lathe CY-K42 CY-K55 – Maiouke

Slant Bed Lathe CY-K55 Manufacturers – YUNNAN Slant Bed Lathe CY-K42 CY-K55 – Maiouke Detail:

Specification

|

Item |

unit |

CY-K42 |

CY-K55 |

|

|

Swing over bed |

mm |

Φ420 |

Φ550 |

|

|

Swing over cross slide |

mm |

Φ250 |

Φ360 |

|

|

Turning Dia. |

mm |

Φ210 |

Φ250 |

|

|

Max. turning Dia. |

Disc |

mm |

Φ320 |

Φ360 |

|

Shaft |

mm |

Φ250 |

Φ320 |

|

|

Dis. between centers |

mm |

400/550 |

550/1050/1550/2050 |

|

|

Max. turning length |

mm |

350/500 |

500/1000/1500/2000 |

|

|

Spindle nose |

A2-6 |

A2-6 |

||

|

Taper hole of spindle |

Φ70, 1: 20 |

Φ70, 1: 20 |

||

|

Spindle bore |

mm |

Φ62 |

Φ62 |

|

|

Maximum diameter of the bar getting through (for hollow chuck) |

mm |

Φ50 |

Φ50 |

|

|

Spindle speed(Imported bearing) |

r/min |

50 ~ 3500 |

50 ~ 3500 |

|

|

Maximum torque of spindle |

Nm |

190 |

190 |

|

|

Spindle steps |

Servo stepless |

Servo stepless |

||

|

Main motor |

Continuous rating |

KW |

11 |

11 |

|

30 minute rating |

KW |

15 |

15 |

|

|

Chuck Dia. |

inch |

8″ |

8″ |

|

|

Rapid feed speed X axis |

m/min |

24 |

24 |

|

|

Rapid feed speed Z axis |

m/min |

24 |

24 |

|

|

Max. travel X axis |

mm |

210 |

250 |

|

|

Max. travel Z axis |

mm |

400/550 |

550/1050/1550/2050 |

|

|

Tailstock quill Dia. |

mm |

Φ55 |

Φ75/Φ110 |

|

|

Tailstock quill Max. travel |

mm |

60 |

100 |

|

|

Tailstock quill taper |

Morse |

4# |

5#/4# Rotary mandrel |

|

|

Guideway Kind |

Rolling Guideway |

|||

|

Turret Method |

Horizontal 8-station |

Horizontal 8-station |

||

|

Dimension of Tool |

Excircle tool |

mm |

25×25 |

25×25 |

|

Boring bar Dia. |

mm |

Φ32 |

Φ40 |

|

|

Chip conveyor Form |

Chip tray |

Chip tray |

||

|

Max. load-bearing disc-type parts |

Kg |

100 |

200 |

|

|

Shaft parts |

Kg |

200 |

500 |

|

|

Machine weight |

Net weight

|

Kg |

2800/3250 |

3700/4700/5200/6000 |

|

Gross weight |

Kg |

3200/3700 |

4200/5200/5800/6800 |

|

|

Center height (The distance of center height to the ground) |

mm |

950 |

1020 |

|

|

Overall dimensions |

Length×Width ×Height |

mm |

2800×1700×1700 3060×1700×1700 |

3250×1800×1850 3850×1800×1850 4250×1850×1900 4950×2000×2000 |

Configuration

Stander configuration● Optional configuration★ Non-optional configuration -

|

Item |

Configuration |

CY-K42 |

CY-K55 |

|

System |

GSK |

● |

● |

|

FANUC |

★ |

★ |

|

|

SIEMENS |

★ |

★ |

|

|

MITSUBISHI |

★ |

★ |

|

|

Main motor |

GSK |

● |

● |

|

FANUC |

★ |

★ |

|

|

SIEMENS |

★ |

★ |

|

|

MITSUBISHI |

★ |

★ |

|

|

Servo Motor |

GSK |

● |

● |

|

FANUC |

★ |

★ |

|

|

SIEMENS |

★ |

★ |

|

|

MITSUBISHI |

★ |

★ |

|

|

Spindle bearing |

Imported |

★ |

★ |

|

Domestic |

● |

● |

|

|

Screw bearing |

Imported |

★ |

★ |

|

Domestic |

● |

● |

|

|

Ball Screw |

Imported |

★ |

★ |

|

Domestic |

● |

● |

|

|

Linear guideway |

Imported |

★ |

★ |

|

Domestic |

● |

● |

|

|

Hard guideway |

Self-made |

★ |

★ |

|

Chuck cylinder |

6″ Solid |

★ |

★ |

|

6″ Hollow |

★ |

★ |

|

|

8″ Solid |

★ |

★ |

|

|

8″ Hollow |

● |

● |

|

|

10″ Solid |

★ |

★ |

|

|

10″ Hollow |

★ |

★ |

|

|

12″ Solid |

- |

★ |

|

|

12″ Hollow |

- |

★ |

|

|

Turret |

Horizontal 8-station servo turret |

● |

● |

|

Horizontal 8-station hydraulic turret |

★ |

★ |

|

|

Horizontal 12-station servo turret |

★ |

★ |

|

|

Horizontal 12-station power turret |

- |

★ |

|

|

Tailstock |

No Tailstock |

★ |

★ |

|

Sleeve retractable hydraulic tailstock |

● |

● |

|

|

Rotary arbor hydraulic tailstock |

★ |

★ |

|

|

Chip catcher Device |

Chip tray |

● |

● |

|

Chip conveyor |

★ |

★ |

|

|

Others |

Grating scale,Tool inspection device,Hydraulic center rest |

||

Characteristic

•Sleeve type spindle unit, standard spindle head is a2-6, optional a2-8.

•It has the characteristics of low temperature rise, small thermal deformation and high precision, so that the spindle can maintain the stability of the spindle axis during long-term operation.

•Optional c-axis function, with band brake.

•The ball screw adopts a pre stretched structure, which can evenly distribute the load to the bearing and maintain high accuracy.

•The turret is equipped with domestic horizontal eight position hydraulic turret as standard, which can be rotated in two directions to select the nearest tool. It has the advantages of high precision, compact structure, and can bear large cutting force.

•Optional servo turret.

•It can also be equipped with a power turret to cooperate with the c-axis and upgrade to a turning center (model k55m/550).

•The standard configuration is sleeve telescopic hydraulic tailstock, which is hydraulically controlled by sleeve expansion; The tailstock is driven to move by the bed saddle through the manual bolt. Optional hydraulic rotary mandrel tailstock, drive tailstock, etc.

•45 ° overall inclined bed structure, rolling guide rail, smooth chip removal, can choose two chip removal methods: rear row and side row.

Product detail pictures:

Related Product Guide:

We stick to our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We aim to create more value for our customers with our rich resources, advanced machinery, experienced workers and excellent services for Slant Bed Lathe CY-K55 Manufacturers – YUNNAN Slant Bed Lathe CY-K42 CY-K55 – Maiouke , The product will supply to all over the world, such as: Albania, Korea, Los Angeles, "Create Values,Serving Customer!" is the aim we pursue. We sincerely hope that all customers will establish long term and mutually beneficial cooperation with us.If you wish to get more details about our company, Please contact with us now!

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.