Slant Bed Lathe CY-K42 Suppliers – YUNNAN Conventional Lathe CY6150B CY6166B CY6176L – Maiouke

Slant Bed Lathe CY-K42 Suppliers – YUNNAN Conventional Lathe CY6150B CY6166B CY6176L – Maiouke Detail:

Characteristic

●The headstock gearbox, block and bed guide are all made of high quality cast iron, all of which are cast by resin sand casting technology and aging process. The bed guide is inductively quenched, and the hardness is around HRC52.

●The spindle is supported by three-point high-precision bearings, and all gears on the headstock are precision ground to make the spindle very smooth when rotating at high speed. High rigidity spindle system with absolute temperature not higher than 35*C.

●Rapid feed system to improve efficiency. Wide range of feed and pitch are available without changing gears, distance between centers 1000 – 5000mm, this lathe covers wide range of working pieces.

●When rapid feeding is on, the tool slide longitudinal travel hand-wheel will be automatically disfunctioned.

●Reliable safety devices, such as foot brakes and emergency power-off switches, are installed. An adjustable overload protection device is also installed in the feed system.

●The tool holder is of ratchet pawl construction and can be re-locked with only half a turn of the lever.

●The tailstock is equipped with a double locking mechanism and an elastic rolling device underneath ensures smooth and effortless movement.

|

item |

unit |

CY6150 |

CY6166 |

CY6176L |

|||||

|

A |

B |

L |

B |

L |

|||||

|

swing over bed |

mm |

500 |

660 |

760 |

|||||

|

swing over cross slide |

mm |

300 |

430 |

530 |

|||||

|

Dis. between centers |

mm |

1000/1500/2000/3000mm |

|||||||

|

spindle nose |

C6 |

D8 |

|||||||

|

Stander 3-jaw chuck |

K11250C/C6 |

K11250C/D8 |

K11325C/D8 |

K11325C/D8 |

K11325C /D8 |

||||

|

Spindle diameter |

mm |

52 |

82 |

105 |

82 |

105 |

105 |

||

|

spindle speed |

rpm |

9-1600 24steps |

9-1600 (24step) |

6-1120 (24steps) |

9-1600 (24steps) |

6-1120 (24steps) |

6-1120 (24steps) |

||

|

Spindle max output torque(30mins) |

N.M |

1400 |

2000 |

2000 |

|||||

|

range of longitudinal feed |

mm/rev |

0-028- 6.43 |

0-028- 6.43 |

0.063- 6.43 |

0-028- 6.43 |

0.063- 6.43 |

0.063- 6.43 |

||

|

range of cross feed |

mm/rev |

0.012- 2.73 |

0.012- 2.73 |

0.012- 2.73 |

0.012- 2.73 |

0.012- 2.73 |

0.012- 2.73 |

||

|

metric threads |

mm |

0.5-224(48kinds) |

0.5-224(48kinds) |

1-224 (48kinds) |

0.5-224(48kinds) |

1-224 (48kinds) |

1-224 (48kinds) |

||

|

Inch system threads |

T.p.i | 72-1/8in(46kinds) | 72-1/8in(46kinds) | 28-1/8in(42kinds) | 72-1/8in(46kinds) | 28-1/8in(42kinds) | 28-1/8in(42kinds) | ||

|

module threads |

0.5-112(42kinds) |

||||||||

|

Dia.pitch threads |

Dp |

56-1/4(45kinds) |

|||||||

|

Main motor |

kw |

7.5 |

7.5 |

11 |

11 |

||||

|

cross slide travel |

mm |

340 |

370 |

||||||

|

Top silde travel |

mm |

145 |

200 |

||||||

|

longitudinal rapid traveling speed |

m/min |

4.5 |

4.5 |

||||||

|

transversal rapid traveling speed |

m/ min |

1.9 |

1.9 |

||||||

|

tailstock quill diameter |

mm |

75 |

75 |

||||||

|

Max travel of tailstock quill |

mm |

150 |

150 |

||||||

|

Taper of tailstock spindle |

M5 |

M5 |

|||||||

|

Cutter size |

mm |

25*25 |

25*25 |

||||||

|

Machine size |

mm |

2500/3000/3500/4500*1150*1300 |

2500/3000/3500/4500*1250*1400(76L:+100 on height) |

||||||

|

Net/gross weight |

kg |

2540/2100 2860/2400 3200/2800 4000/3800 |

2800/2200 3000/2500 3400/2900 4200/3400(76L:+100 on both) |

||||||

|

Wroking roundness |

0.01 |

||||||||

|

Working cylindricity |

0.04/300 |

||||||||

|

Working flatness |

0.025/Φ300 |

||||||||

|

Accuracy stander |

GB/T4020-1997 |

||||||||

Stander Configuration

1. 250mm 3-jaw chuck for 50B,50L series;325mm 3-jaw chuck for 66B, 66L, 76L series

2. Thread chasing dial

3. Chip guard for L≤2m lathe,follow chip guard for L≤3m lathe

4. Foot brake

5. Oil gun

6. Live center 5#

7. Center 5#

8. Center sleeve

Optional Configuration

1. 630mm Face plate for 50 series

800mm Face plate for 66, 76 series

2. 400mm 4-jaw chuck

3. 20-140mm Small steady rest

4. 130-260mm Large steady rest

5. 2680mm Follow rest

6. 250mm Drive plate

7. 4-position stop for saddle

8. 4-position stop for cross slide

9. Micro stop for saddle

10. Quick change tool post

11. Damping washer

12. Taper turning attachment(TTA)

13. Halogen work lamp

14. Digital readout(DRO)

15. CE standard compliance

16. Chuck cover

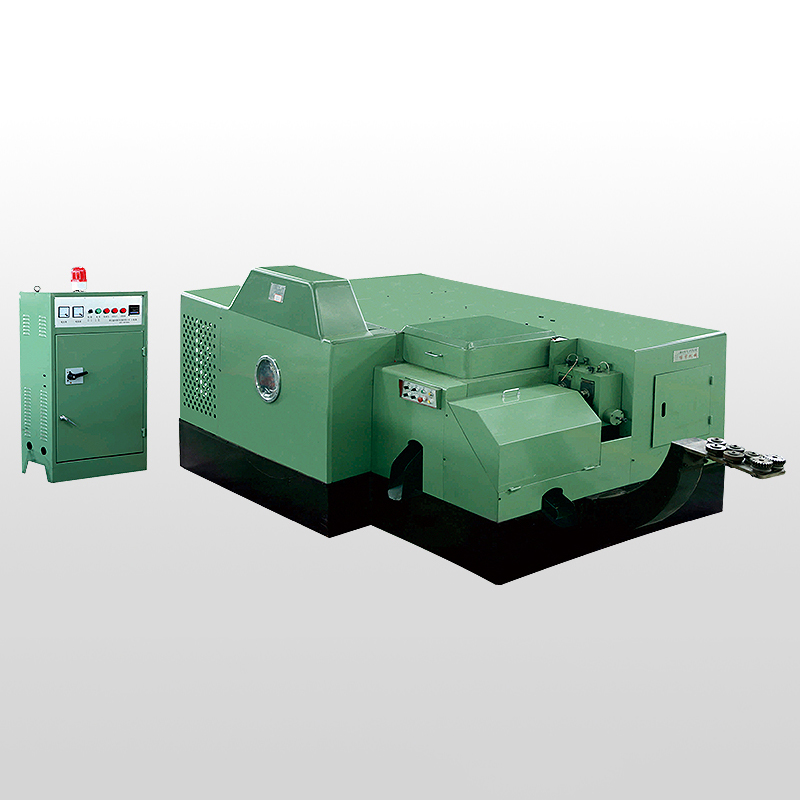

Product detail pictures:

Related Product Guide:

Our growth depends around the superior machines, exceptional talents and consistently strengthened technology forces for Slant Bed Lathe CY-K42 Suppliers – YUNNAN Conventional Lathe CY6150B CY6166B CY6176L – Maiouke , The product will supply to all over the world, such as: Iran, Haiti, Austria, Please really feel free to send us your requirements and we'll respond to you asap. We have got a professional engineering group to serve for your just about every detailed needs. Cost-free samples could be sent for you personally to understand much more information. In an effort to meet your requires, please really feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd items. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is actually our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!