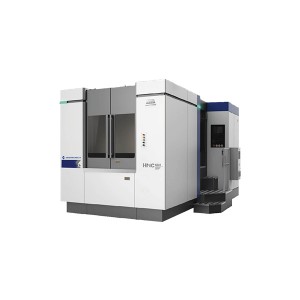

SHENYANG (SYMG) HTC40bm 500mm Horizontal CNC Mill Turning Machine Center

| Model NO. | HTC40Bm – 500 | After – sales Service | 1 Year |

| Warranty | 1 Year | Application | Metal |

| Process Usage | Metal – Cutting CNC Machine Tools, CNC Non – Conventional Machine Tools, Metal – Forming CNC Machine Tools | Numerical Control | CNC/MNC |

| Condition | New | Max Swing Over Bed | 600 mm |

| Cutting Length | 500 mm | Cutting Diameter | 400mm |

| Max Swing Over Slide Diameter | 320mm | Spindle Nose | A2 – 8 |

| Spindle Bore | 80 mm | Bar Through Diameter | 50 mm |

| Speed | 50 – 3500 R/Min | Max Output Torque | 245 Nm |

| Steps | Stepless | Power | 15(30min)/11(Rated) Kw |

| Diameter | 8” | X – Axis Max Travel Speed | 30 M/Min |

| Z – Axis Max Travel Speed | 30 M/Min | X – Axis Travel | 200 mm |

| Trademark | SHENYANG(SYMG) | Origin | Shenyang, China |

Product Description

HTC40 series CNC slant lathe is a high-quality product designed and produced in accordance with the market and development needs by combining our experience in designing horizontal CNC horizontal lathes for many years. The newly designed host structure and reliable assembly process have made htc40 series machine tools fully upgraded. With stable and reliable product performance and innovative ergonomic design, htc40B series will undoubtedly become the best in the industry.

Specification

| Items | Units | HTC40Bm-500 |

| Length specification | mm | 500 |

| Maximum swing diameter over bed | mm | Φ600 |

| Maximum cutting length | mm | 500 |

| Maximum cutting diameter | mm | Φ400 |

| Maximum swing diameter over cross slide | mm | Φ320 |

| Spindle nose type and code | - | A2-8 |

| Spindle bore diameter | mm | Φ80 |

| Maximum bar stock passing diameter | mm | Φ50 |

| Headstock | ||

| Spindle speed range | r/min | 50-3500 |

| Maximum output torque of spindle | Nm | 245 |

| Spindle speed steps | - | Infinitely variable speeds |

| Main motor power | kw | 15(30minutes)/11(rated) |

| Chuck | ||

| Chuck diameter/type | inch | 8″ |

| X-axis rapid traverse speed | m/min | 30 |

| Z-axis rapid traverse speed | m/min | 30 |

| X-axis travel | mm | 200 |

| Z-axis travel | mm | 550 |

| Tailstock sleeve travel | mm | 100 |

| Tailstock sleeve taper | morse | 5# |

| Standard tool post type | Horizontal 12-position | |

| Machining Accuracy | IT6 | |

| Positioning Accuracy | ||

| X-axis | mm | 0.008 |

| Z-axis | mm | 0.008 |

| C-axis | 63″ | |

| Repeat Positioning Accuracy | ||

| X-axis | mm | 0.004 |

| Z-axis | mm | 0.004 |

| C-axis | 25″ | |

| Tool size | ||

| Cylindrical turning tool | mm | 25 x 25 |

| Boring tool bar diameter | mm | Φ40/Φ32/Φ25/Φ20 |

| Processing capacity | ||

| Maximum drilling capacity | mm | 12×0.2 |

| Maximum milling capacity | mm | 12×10×40 |

| Maximum tapping capacity | mm | M10×1.5 |

| Whether cutter head is able to select cutter handily | - | Yes |

| Maximum load capacity | ||

| Disc workpieces | kg | 200 |

| Shaft workpieces | kg | 500 |

| Machine weight | kg | 4200 |

| Overall dimension (L x W x H) | mm | 2700 x 1900 x 2100 |

Characteristic

This machine tool can process shaft and disk parts, turn threads, arcs, cones and internal and external surfaces of rotating bodies, and process rotating body parts efficiently, in large quantities and with high accuracy. In the design, the rigidity of the main shaft, bed, tailstock and other components are reasonably matched, which greatly improves the rigidity of the whole machine and ensures the stability during re cutting. Therefore, the machining accuracy of this machine tool can reach IT6 ~ IT7. As a general-purpose machine tool, it is especially suitable for automobile, motor, bearing, hydraulic and other industries to process rotating parts with high efficiency, large batch and high precision.