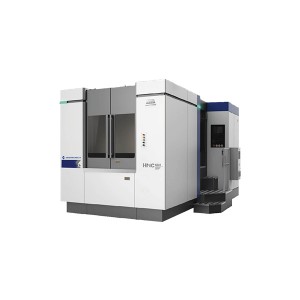

SHENYANG (SMTCL) T5.2 500 Sm Mill Turning Center Horizontal CNC Milling Machine

| Model NO. | T5.2 500 Sm | After – sales Service | 1 Year |

| Warranty | 1 Year | Application | Metal |

| Process Usage | Metal – Cutting CNC Machine Tools, CNC Non – Conventional Machine Tools, Metal – Forming CNC Machine Tools | Numerical Control | CNC/MNC |

| Condition | New | Maximum Turning Diameter | 380 |

| Trademark | SHENYANG(SYMG) | Origin | Shenyang, China |

Product Description

The new generation of T5-Q/S series universal horizontal CNC lathe is scientifically and reasonably analyzed and optimized through professional design and analysis software, and assembly verification and improvement are carried out with advanced manufacturing and testing technology. It has good cutting performance, can meet the processing requirements of various rotary parts, and provide customers with the best processing experience.

T5.1-Q series horizontal CNC lathe covers a small area and is suitable for high-precision processing of various small parts, effectively meeting the processing needs of automobile, bearing, hardware, medical and other industries. T5.2-Q series horizontal CNC lathe is applicable to processing various shaft and disc parts, effectively meeting the processing requirements of ball cage, automobile mandrel, motor shaft, half shaft, gear shaft, valve tappet and other parts.The feeding part of T5.2-S series horizontal CNC lathe adopts a rigid rail structure, which is suitable for processing various shaft and disc parts, and can effectively meet the processing requirements of parts in automobile, bearing, engineering machinery and other industries.

| Items | Units | T5.2-500 Sm | T5.2-1000Sm |

| Maximum turning diameter | mm | Φ320 | Φ380 |

| Maximum turning length | mm | 500 | 500 |

| Maximum swing diameter over bed | mm | Φ560 | Φ560 |

| Maximum swing diameter over cross slide | mm | Φ400 | Φ400 |

| Spindle | |||

| Spindle nose type and code | A2-8 | A2-8 | |

| Inner diameter of front bearing | mm | 120 | 120 |

| Spindle front hole taper and taper hole | 1:20;Φ90 | 1:20;Φ90 | |

| Spindle bore diameter | mm | Φ80 | Φ80 |

| Maximum bar stock passing diameter | mm | Φ65 | Φ65 |

| Chuck diameter | inch | 8 | 10 |

| Maximum spindle revolutions | r/min | 4000 | 4000 |

| Rated torque of spindle | Nm | 178 | 180(769r/min) |

| Maximum torque of spindle | Nm | 295 | 300(576r/min) |

| Main motor output power continuous/15 minutes | kw | 15/18.5 | 18.5 |

| Two-axis | |||

| X/Z axis rapid traverse speed | m/min | 20 | 20 |

| X-axis travel | mm | 200 | 200 |

| Z-axis travel | mm | 560 | 1025 |

| Machining Accuracy | - | IT6 | IT6 |

| Positioning Accuracy | |||

| X-axis | mm | 0.01 | 0.01 |

| Z-axis | mm | 0.01 | 0.01 |

| C-axis | 40″ | 40″ | |

| Repeat Positioning Accuracy | |||

| X-axis | mm | 0.005 | 0.005 |

| Z-axis | mm | 0.006 | 0.006 |

| C-axis | 28″ | 28″ | |

| Tailstock | |||

| Tailstock travel | mm | 350 | 770 |

| Tailstock sleeve travel | mm | 100 | |

| Tailstock sleeve diameter | mm | Φ100 | |

| Tailstock drive mode | Bed saddle dragging | Bed saddle dragging | |

| Tailstock taper | morse | MT-4 | MT-4 |

| Power Tool Turret | |||

| Type | Horizontal 12-position | Horizontal 12-position | |

| Center height | mm | 100 | 80 |

| Repeatability accuracy of turret rotation | Sec. | ±1.6 | ±1.6 |

| Max drilling capacity | mm × mm/u |

14×0.15 | 14×0.15 |

| Max milling capacity | mm | 20×10×40 | 20×10×40 |

| Whether cutter head is able to select cutter handily |

- | Yes | Yes |

| End-face tool holder | mm | 25*25 1pc | 25*25 1pc |

| Outer circal tool holder | mm | 25*25 3pcs | 25*25 3pcs |

| Boring tool holder | mm | Φ40 3pcs | Φ32 3pcs |

| Power milling head | - | 0° 90° 1pc | 0° 90° 1pc |

| Coolant and chip removal | |||

| Pressure of cooling pump | bar | 3 | 3 |

| Flow of cooling pump | - | 66 | 66 |

| Water tank capacity | - | 200 | 200 |

| type of chip conveyor | - | Chain-plate | Chain-plate |

| Other | |||

| distance from spindle center to bed bottom | mm | 1015 | 1015 |

| Machine weight | kg | 4300 | 5000 |

| Total power capacity | kVA | 42 | 42 |

| Overall dimension (L × W × H) | mm | 2870 × 1890 × 1900 | 3750 × 1890 × 1900 |