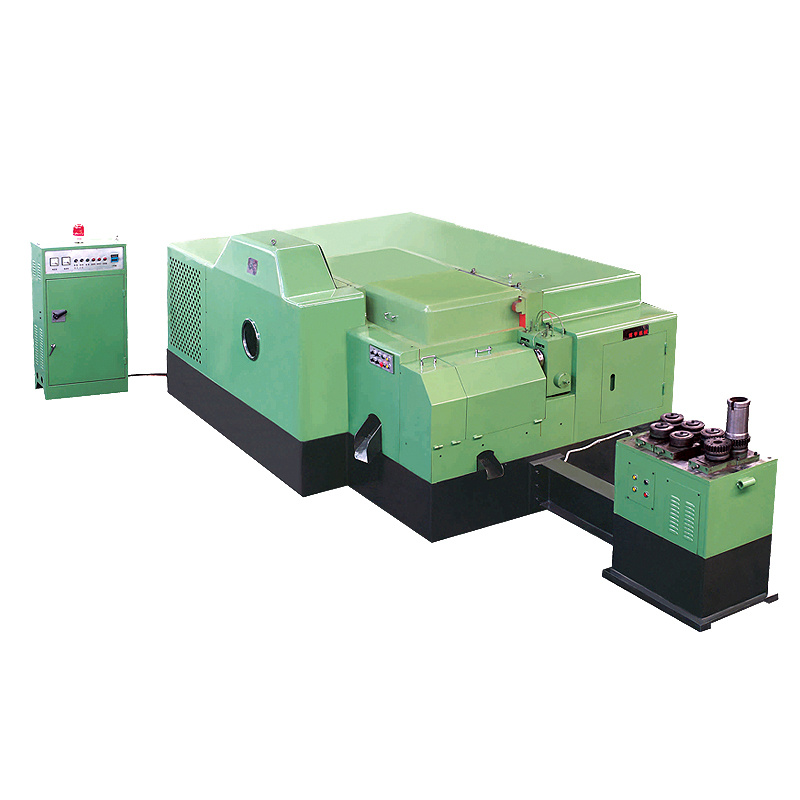

A Cold Heading Machine is a specialized metal forming machine used to produce fasteners and other precision components such as bolts, screws, rivets, and pins without the need for heating the material. Instead of cutting or machining, it forms the metal by applying high pressure to reshape it while it remains at room temperature.

Working Principle

The cold heading process begins with a wire or metal rod that is cut into a specific length and then fed into the machine. The material is forged and shaped through a series of dies and punches.

During this process:

-

The material is upset (compressed) to form the head of the part.

-

It can be further processed through multiple stations to create different shapes, threads, or other required features.

-

The result is a component with high dimensional accuracy, excellent surface finish, and improved mechanical strength.

Because the metal is not heated, the grain structure remains continuous, resulting in stronger parts compared to those made by cutting.

Features and Advantages

-

High production efficiency — ideal for mass production.

-

Consistent and precise dimensions.

-

Improved material utilization with minimal waste.

-

Enhanced tensile strength due to cold working.

Suitable for various materials such as carbon steel, stainless steel, copper, and aluminum.

Applications

Cold heading machines are widely used in industries such as:

-

Automotive – producing bolts, nuts, and screws for engines and chassis.

-

Construction – making anchors, rivets, and fasteners.

-

Electronics – manufacturing small precision parts.

-

Machinery manufacturing – producing shafts, pins, and connectors.

With our years of experience in metal forming equipment, we provide customized cold heading solutions that meet diverse production needs. Each machine is tested for performance, precision, and safety — helping our customers increase productivity and reduce manufacturing costs.

Welcome to contact us or visit our factory for more information and demonstrations.

Post time: Oct-31-2025