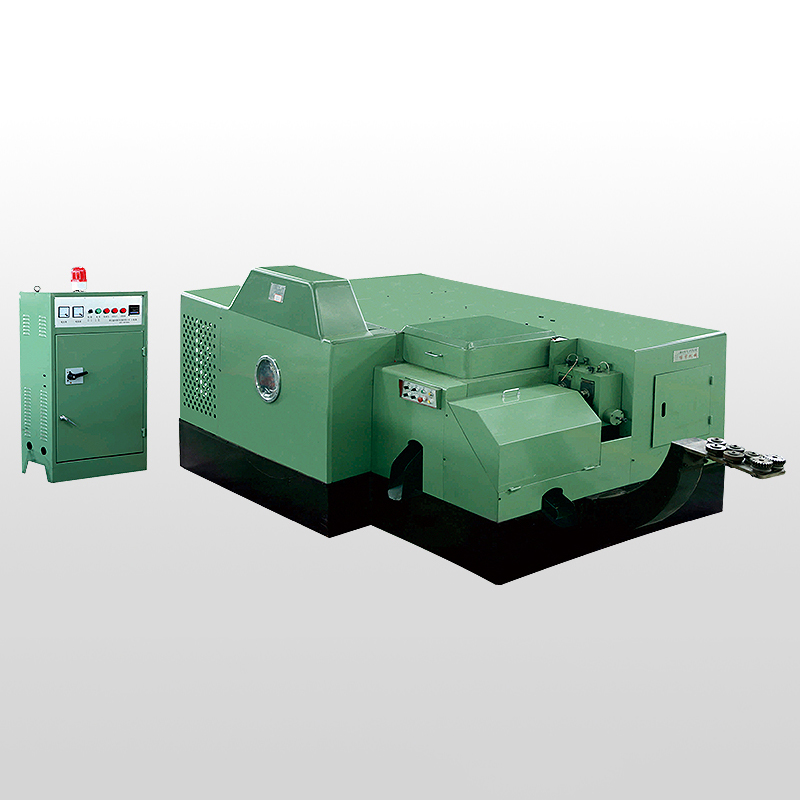

Double Disc Grinding Manufacturer – YUHUAN Double Disc Grinding machine YHDM580E – Maiouke

Double Disc Grinding Manufacturer – YUHUAN Double Disc Grinding machine YHDM580E – Maiouke Detail:

Characteristic

1. C-type grinding and continuous grinding (optional swing grinding, double planetary grinding), to achieve high precision and efficient grinding;

2. Large window at the backside to change grinding wheel, Fixed feeding carrier, convenient for supporting automation.

3. The upper box, the lower box and the feeding carrier are respectively vertically connected and fixed to ensure the smooth operation of machine.

4. Linear dressing mechanism with multiple groups of oilstones at the same time, high dressing efficiency.

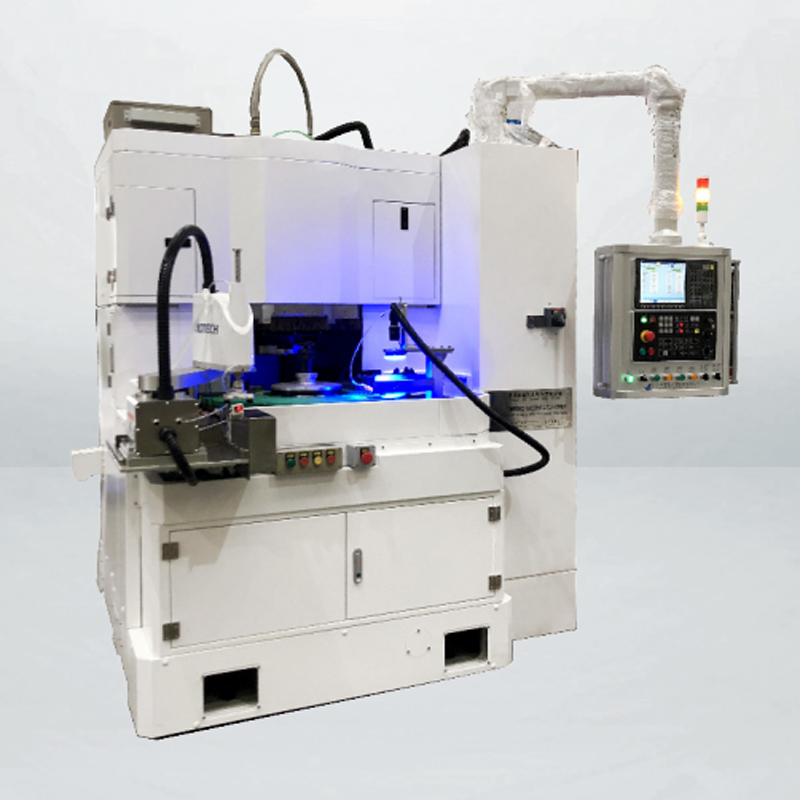

5. Siemens NUMERICAL control system (optional Central China system), simple operation, powerful and perfect.

6. Servo motor is used to control the reducer to drive the lead screw and screw nut to push the grinding head to move up and down. Precision linear grating ruler is equipped to ensure micron feeding accuracy.

7. The high rigidity and large torque electric spindle is used to replace the ordinary mechanical spindle, which runs smoothly and eliminates the vibration of the machine tool caused by the transmission chain, thus improving the grinding efficiency and accuracy.

8. The spindle center delivers water to improve grinding efficiency.

|

Items |

Unit |

YHDM580E |

|

Workpiece size(Diameter) |

mm |

Φ20-Φ150 |

|

Workpiece thickness |

mm |

0.8-40 |

|

Grinding wheel size |

mm |

Φ585×Φ180 |

|

Grinding motor power |

kw |

30Kw×2 |

|

Grinding motor speed |

rmp |

50-1500 |

|

Feeding carrier motor power |

kw |

1.5 |

|

Weight |

kg |

4800 |

|

Overall dimension (L×W×H) |

mm |

1880×2430×2350 |

Processing type

Grinding Structure

Machinery Precision and Stability

1. The machine adopts box structure with vertical spindle for upper & lower grinding.

2. The spindle structure is a combination of double cylindrical roller bearing and double direction angular contact thrust ball bearing, ensuring the stability & rigidity of the grinding heads.

3. The main motor transmits the torque to the spindle through triangular belt-wheel. And unloading structure is adopted between triangular belt-wheel and splines to avoid bending load on the spindle.

4. Grinding head feeding cotrolled by high-precision ball screw unit, with feeding precision up to 0.001mm, which secures the stability of grinding process.

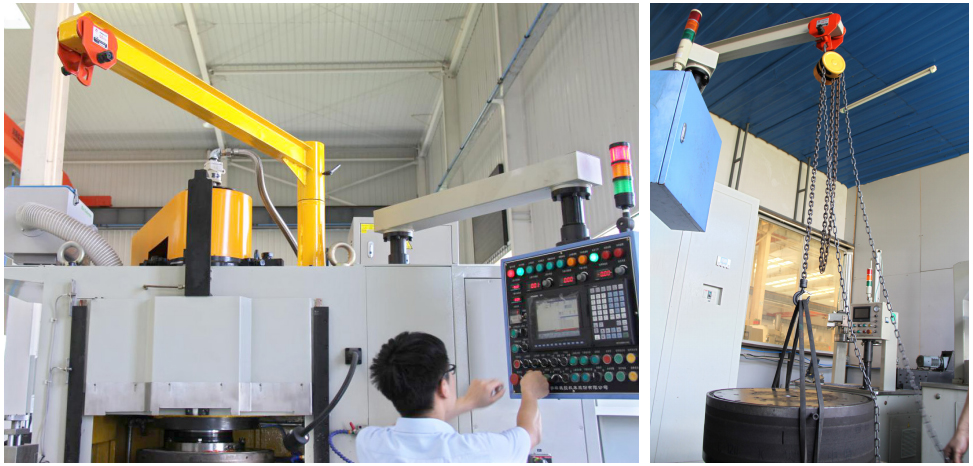

Installation of Grinding Wheel

Integrated crane is equipped for unloading/loading of the abrasive wheels. Unique swing-out structure for the feeding carrier provides outstanding space for tool changes. Portable wheel changing aid for rapid & easy transportation of the tools, reducing labor intensity and improving work efficiency.

Product detail pictures:

Related Product Guide:

With state-of-the-art technologies and facilities, strict good quality regulate, reasonable cost, exceptional assistance and close co-operation with prospects, we're devoted to supplying the top benefit for our customers for Double Disc Grinding Manufacturer – YUHUAN Double Disc Grinding machine YHDM580E – Maiouke , The product will supply to all over the world, such as: Canada, Surabaya, Macedonia, We pay high attention to customer service, and cherish every customer. We have maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.