Deep Hole Drilling Machine Suppliers – XINYUE spline cold rolling machine CZ-16MY 24MY 36MY 48MY – Maiouke

Deep Hole Drilling Machine Suppliers – XINYUE spline cold rolling machine CZ-16MY 24MY 36MY 48MY – Maiouke Detail:

Specification

|

Technical Parameter |

Unit |

CZ-16MY |

CZ-24MY |

CZ-36MY |

CZ-48MY |

|

Loaded Tool Length |

Inch |

16 |

24 |

36 |

48 |

|

Max. Module |

m |

1.0 |

1.25 |

1.75 |

2.00 |

|

Max. Teeth Diameter |

mm |

22 |

40 |

50 |

60 |

|

Workpiece Length |

mm |

800 |

800 |

800 |

800 |

|

Cylindricity |

mm |

0.01 |

0.015 |

0.015 |

0.02 |

|

Roughness |

μm |

0.4-1.6 |

0.4-1.6 |

0.4-1.6 |

0.4-1.6 |

|

Max. Roll Forming Length |

mm |

80 |

100 |

120 |

150 |

|

Roll Forming Capacity Factor |

mm |

35 |

50 |

70 |

100 |

Characteristic

1. Increase Tool Mounting Space

16 “/ 24″ / 36 “/ 48″ roll forming tools can be mounted on the machine to complete roll forming processes of multi position splines with different parameters.

2. Optimized Hydraulic Transmission

Customized special hydraulic drive unit consists of imported hydraulic components. Upgraded hydraulic system has a clearer oil piping layout, more properly designed back pressure and buffering and the cylinder propulsion is improved so that the main slider travels very smoothly. And at the same time the noise is greatly reduced.

3. Perfect Synchronization Mechanism

Original Swiss high-precision racks and pinions ensure synchronization of the displacement of the upper and lower cutting tools, which makes the machines runs stabler with optimized hydraulic power.

4. Optimized Hydraulic Power

Multi-stage processing technology reduces labor intensity, making it possible for a person to operate multiple devices; and it also reduces product flow, uses less procedures and reduces product clashes.

5. Horizontal Pre-Pull Structure

The optimized internal stiffener arrangement and six-sided frame, and domestic patented combination sliding stud connection greatly enhance the overall rigidity, stability, reliability, security, which guarantees a longer service life of the machine.

6. User-Friendly Operation Interface

The system can display fault information, processing count, timing, storage program, detection of the total length of the workpiece, anti- faulty or empty clamping, self-learning and so on.

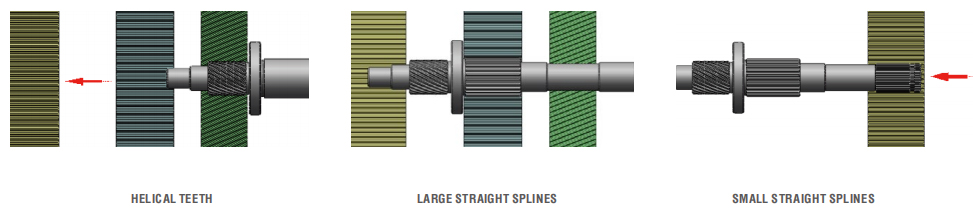

Parts Machined By Roll Forming Machine

Suitable for straight teeth and helical gear teeth on various shaft parts such as gearbox gear shaft, cage constant velocity universal joint, spline shaft, motor shaft, textile roller, spring torsion bar, steering gear, crankshaft, etc.

XINYUE TECHNOLOGY

XINYUE Precision roll forming machine is the most ideal cold forming machinery for production of precision splines at home and abroad. It has: reasonableness of forming principles; achievability and retentionability of high precision forming; forming feasibility at low pressure angle; practicality for repeated die use; quick die replacement without the need for tooth aligning and tooth calibrating;highly efficient and safe automatic feeding mechanism; long and reliable equipment life; combined modular structure easy for maintenance; wide applications, unparalleled operation and process advantages over traditional wheel spline roll milling machines and other cold forming spline processes; advanced precision spline cold roll forming process widely adopted at home and abroad, over 30 times efficiency (about 10-20 s per workpiece) than that of traditional cutting process, 40% higher in load bearing than cutting processed workpieces, less than Ra 4.0 in roughness, 9%-15% material saving; cold forming for splines, threads, ruled surfaces, twilled surfaces, grooves, straight teeth , helical teeth, cold roll forming, etc.

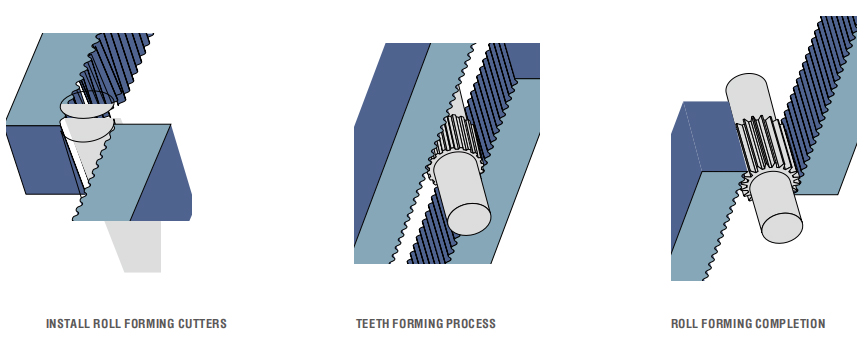

Roll forming machine roll forming process

Multi-stage roll forming process

Processing principles

The principles of cold-roll forming are that the roll forming cutter dies installed on the sliding table operate in opposite linear motion. The workpiece splines are formed by the increasing teeth amount of the roll forming cutters, and the final shaping precision and stability of the splines are obtained by the rigid distance between the two roll forming cutters. The opposite linear movements of the roll forming cutters are driven by hydraulic machine and the high synchronization of the two roll forming cutters is guaranteed by the racks and pinions. The synchronization of two roll forming cutters is guaranteed by the ball screws on the CNC machine. (Its synchronization accuracy is higher).

Product detail pictures:

Related Product Guide:

"Quality to start with, Honesty as base, Sincere company and mutual profit" is our idea, as a way to build constantly and pursue the excellence for Deep Hole Drilling Machine Suppliers – XINYUE spline cold rolling machine CZ-16MY 24MY 36MY 48MY – Maiouke , The product will supply to all over the world, such as: St. Petersburg, Anguilla, Durban, We have 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export products to other countries. We expect to cooperate with you to develop a larger market.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.