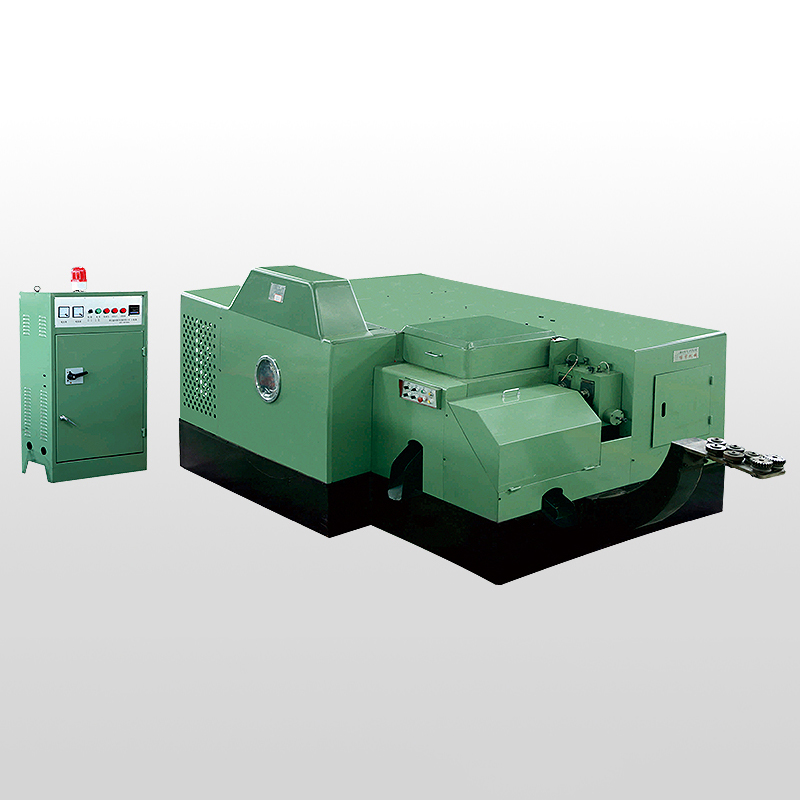

Cold Forging Machine Manufacturer – XINYUE Double-Sided CNC Lathe SC32-300 SC72-400 SC130-400 – Maiouke

Cold Forging Machine Manufacturer – XINYUE Double-Sided CNC Lathe SC32-300 SC72-400 SC130-400 – Maiouke Detail:

Specification

|

Technical Parameter |

Unit |

SC32-300 |

SC72-400 |

SC130-400 |

|

Maximum clamping diameter |

mm |

32 |

72 |

130 |

|

Maximum machining length |

mm |

300 |

400 |

400 |

|

Minimum processing length |

mm |

100 |

200 |

200 |

|

Maximum spindle speed |

R/min |

3500 |

2000 |

1200 |

|

Spindle motor power |

kw |

5.5 |

5.5 |

7.5 |

|

Z axis fast travel |

m/min |

16 |

16 |

16 |

|

X axis fast travel |

m/min |

16 |

16 |

16 |

|

Z axis max. guide travel |

mm |

400 |

400 |

400 |

|

X axis max. guide travel |

mm |

300 |

300 |

300 |

|

Machine weight |

kg |

4000 |

4000 |

4500 |

|

Machine Dimension |

mm |

2800×2080×1695 |

2800×2080×1695 |

2800×2080×1695 |

|

Please note: The maximum processing length is customized according to customer requirements. |

||||

Characteristic

The double sided turning machine with centered spindle, two Z-axises, two X-axises and two-way moving pallets has characteristics of high precision, high efficiency, high rigidity, etc.

1. Processing is carried out on both ends of the rotating workpiece, which can achieve high concentricity.

2. Double end processing doubles efficiency.

3. The simultaneously processed center holes, threads, inner holes, external circles end faces can have a concentricity ≤0.01.

4. Simultaneous processing of inner holes, female threads can be achieved for pipes and sleeve parts, with a concentricity ≤0.01.

5. Ramp rail layout, high rigidity, high precision are very conducive to chip removal.

6. Smart double channel system is simple for operation.

7. Imported linear guides and guide screws are used to guarantee precision and stability of the machine.

8. Hydraulic or pneumatic workpiece clamping mechanisms are provided for convenient clamping.

9. Automatic chip removal.

10. Automatic forced lubrication.

11. High clamping accuracy ≤0.015.

12. Flexible Fast Rubber Clamps

The rubber clamps are easy for handling.The machine adopts hydraulic or pneumatic clamping, which is fast, stable and safe.

13. Centered Spindle (Bidirectional Spindle)

Optional bearing and static pressure spindles can process on both sides with high effi ciency, high precision.

14. Optional Tool Turret

Flexible tool adaption solution that meets complex part processing.Inside turret water cool, which cools thoroughly.

15. Design Of Tool Arranging And Mounting

Design of tool arranging and mounting enables customers to use easily, which is cost-effective, stable and durable.

16. Inverted Vertical Structure, More Smooth Chip Removal

This machine adopts special double channel numerical control system with convenient programming and formidable functions.

Parts Machined By Roll Forming Machine

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Cold Forging Machine Manufacturer – XINYUE Double-Sided CNC Lathe SC32-300 SC72-400 SC130-400 – Maiouke , The product will supply to all over the world, such as: Ghana, USA, Japan, Please feel cost-free to send us your specifications and we'll respond to you asap. We've got a professional engineering team to serve for the every single detailed needs. Free samples may be sent for you personally to know far more facts. So that you can meet your desires, please really feel cost-free to contact us. You could send us emails and call us straight. Additionally, we welcome visits to our factory from all over the world for much better recognizing of our corporation. nd merchandise. In our trade with merchants of several countries, we often adhere to the principle of equality and mutual advantage. It is our hope to market, by joint efforts, both trade and friendship to our mutual benefit. We look forward to getting your inquiries.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.