CNC Economical Lathe CY-K510N Supplier – YISHUI CNC Pipe Threading Lathe QK1319 1332 QKD1335 QK1350 – Maiouke

CNC Economical Lathe CY-K510N Supplier – YISHUI CNC Pipe Threading Lathe QK1319 1332 QKD1335 QK1350 – Maiouke Detail:

Specification

|

Item |

Unit |

QK1319 |

QK1322 |

QKD1335 |

QK1350 |

|||

|

Manual |

HYD |

Manual |

HYD |

|||||

|

Capacity |

Swing over bed |

mm |

630/800 |

630/800 |

900 |

1200 |

||

|

Swing over cross slide |

mm |

340/520 |

340/520 |

535 |

710 |

|||

|

Distance between centers |

mm |

1000-6000 |

1000-6000 |

1000-3000 |

1500/3000 |

|||

|

Guideway width |

mm |

50-193 |

50-220 |

110-340 |

330-510 |

|||

|

Max. load capacity |

mm |

550 |

550 |

755 |

765 |

|||

|

Spindle bore |

T |

3 |

3 |

5 |

6 |

|||

|

Spindle |

Spindle bore taper |

mm |

206 |

206 |

355 |

520 |

||

|

Spindle nose type |

- |

VF.4 steps |

HYD 4 steps |

VF.4 steps |

HYD 4 steps |

Stepless |

VF.3 steps |

|

|

Spindle speed range |

rpm |

20-600 |

20-600 |

90-450 |

8-190 |

|||

|

Chuck |

mm |

Φ500 3-jaw manual |

Φ500 3-jaw manual |

Φ780 4-jaw electric |

Φ1000 4-jaw electric |

|||

|

Turret |

Turret/tool post |

- |

NC turret 4 position |

NC turret 4 position |

NC turret 4 position |

NC turret 4 position |

||

|

Tool shank size |

mm |

32×32 |

32×32 |

40×40 |

50×50 |

|||

|

Feed |

X axis travel |

mm |

320/420 |

320/420 |

480 |

520 |

||

|

Z axis travel |

mm |

1000-6000 |

1000-6000 |

1000-3000 |

1250/2750 |

|||

|

X axis rapid traverse |

mm/min |

4000 |

4000 |

4000 |

4000 |

|||

|

Z axis rapid traverse |

mm/min |

6000 |

6000 |

6000 |

4000 |

|||

|

Tailstock |

Tailstock quill diameter |

mm |

Φ100 |

Φ100 |

- |

Φ160 |

||

|

Tailstock quill taper |

- |

MT5/MT6 |

MT5/MT6 |

- |

MT6 |

|||

|

Tailstock quill travel |

mm |

250 |

250 |

- |

300 |

|||

|

Motor |

Main spindle motor |

kW |

11 |

11 |

22 |

22 |

||

|

Coolant pump motor |

kW |

0.25 |

0.25 |

0.25 |

0.25 |

|||

|

Dimension |

Width×Height |

mm |

1880×1850 |

1880×1850 |

2050×2050 |

2300×2200 |

||

|

Length |

mm |

3300-8300 |

3300-8300 |

3952-5950 |

5000/6500 |

|||

|

Weight |

Net weight |

T |

4.6-8.6 |

4.7-8.7 |

10.9 |

15.0/16.0 |

||

|

Please note: machine bed length can customize according to real work demand, machine on this page can choose servo motor direct driving structure turning center with C axis.(QK1319 QK1322) machine bed length can customize according to real work demand, extra-long bed heavy duty lathe can customize simplified CNC pipe threading lathe without protective cover.(QK1350) |

||||||||

Characteristic

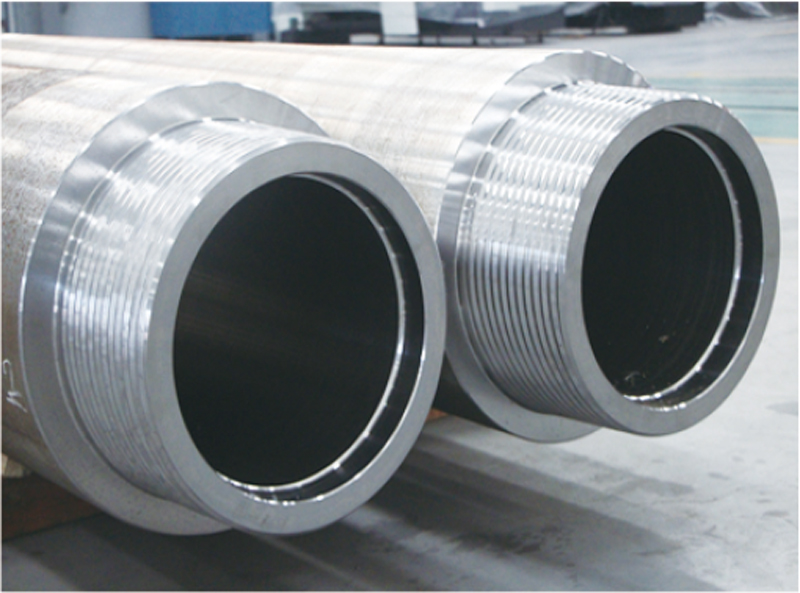

●Big spindle bore and double chuck to ensure process big diameter pipe.

●One-piece bed adopts high strength iron to ensure rigidity and precision.

●Ultrasonic frequency quenched guide-ways ensure good wear-resistance.

●Carriage and guide way contact surface use Turcite B to maintain accuracy.

Stander Configuration

1. Siemens controller

2. NC turret

3. Automatic Lubrication

4. Coolant Pump

5. Semi-shield

Optional Configuration

1. Fanuc or other brand CNC controller

2. Quick change tool post

3. Hydraulic turret or Power turret

4. Pneumatic chuck

5. Hydraulic tailstock

6. Pneumatic position limiter

7. Tool setting arm

8. Full-shield

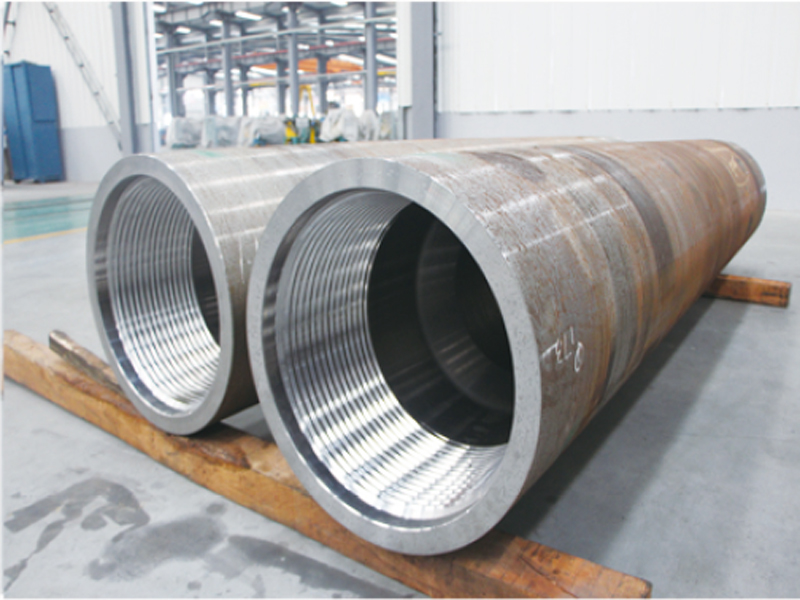

Product detail pictures:

Related Product Guide:

We constantly continually give you essentially the most conscientious client provider, plus the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for CNC Economical Lathe CY-K510N Supplier – YISHUI CNC Pipe Threading Lathe QK1319 1332 QKD1335 QK1350 – Maiouke , The product will supply to all over the world, such as: Bangladesh, Mozambique, Russia, Till now, the goods list has been updated regularly and attracted clients from around the globe. Detailed facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are going to help you get comprehensive acknowledge about our products and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!