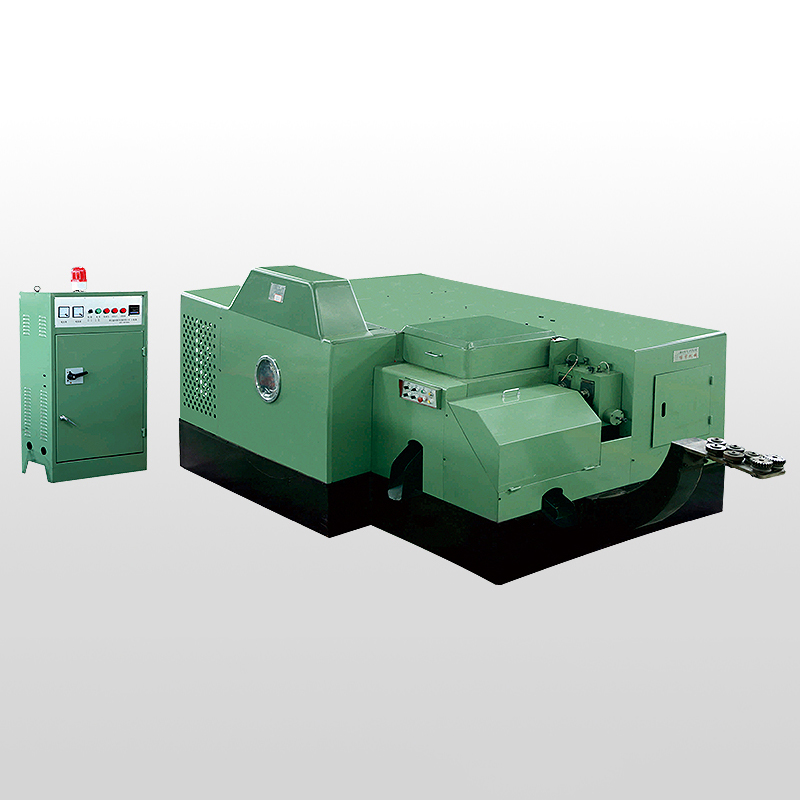

China Double Disc Grinder Manufacturer – YUHUAN Precision Double Disc Grinder YHDM580B YHDM580B/3 YHDM580B/5 – Maiouke

China Double Disc Grinder Manufacturer – YUHUAN Precision Double Disc Grinder YHDM580B YHDM580B/3 YHDM580B/5 – Maiouke Detail:

Characteristic

1. The body adopts castings box structure, good shock absorption, rigidity and reliable thermal stability.

2. The coolant is filtered by magnetic separation and paper tape filtration, and recycled after temperature control of the coolant.

3. Hinged disc feeding mechanism, flexible opening, convenient replacement and dressing grinding wheel.

4. Equipped with automatic grinding wheel dressing device, convenient and fast, to ensure the grinding wheel correction quality.

5. In addition to the spindle motor, each transmission chain is driven by servo motor, smooth movement, accurate positioning, convenient adjustment.

|

Items |

Unit |

YHDM580B |

|

Workpiece size(Diameter) |

mm |

Φ12-Φ120 |

|

Workpiece size(Diameter) |

mm |

0.8-40 |

|

Grinding wheel size |

mm |

Φ585×Φ195 |

|

Grinding motor power |

kw |

22Kw×2 |

|

Grinding motor speed |

rmp |

50-950 |

|

Feeding carrier motor power |

kw |

1.5 |

|

Weight |

kg |

8000 |

|

Overall dimension (L×W×H) |

mm |

2250×2300×2880 |

Processing type

Typical applications

Tool Structure

Machinery Precision and Stability

1. The machine adopts box structure with vertical spindle for upper & lower grinding.

2. The spindle structure is a combination of double cylindrical roller bearing and double direction angular contact thrust ball bearing, ensuring the stability & rigidity of the grinding heads.

3. The main motor transmits the torque to the spindle through triangular belt-wheel. And unloading structure is adopted between triangular belt-wheel and splines to avoid bending load on the spindle.

4. Grinding head feeding cotrolled by high-precision ball screw unit, with feeding precision up to 0.001mm, which secures the stability of grinding process.

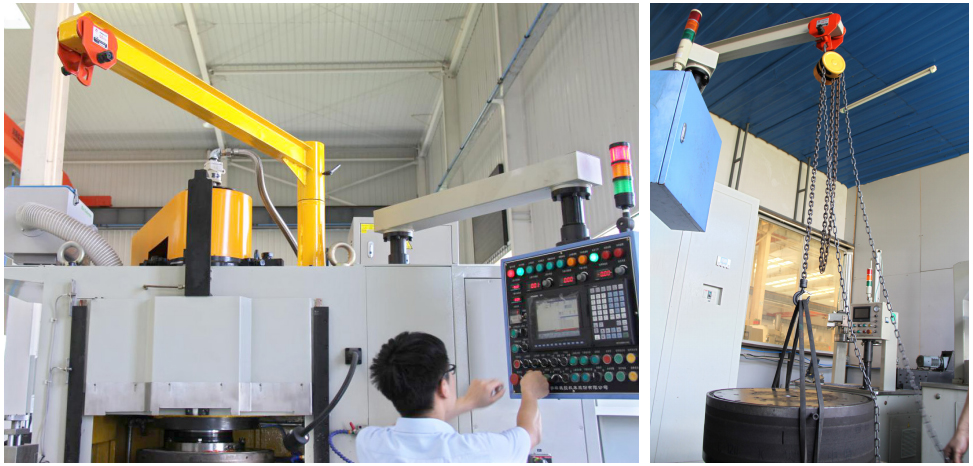

Installation of Grinding Wheel

Integrated crane is equipped for unloading/loading of the abrasive wheels. Unique swing-out structure for the feeding carrier provides outstanding space for tool changes. Portable wheel changing aid for rapid & easy transportation of the tools, reducing labor intensity and improving work efficiency.

Product detail pictures:

Related Product Guide:

Our rewards are lower costs,dynamic profits team,specialised QC,potent factories,high-quality services for China Double Disc Grinder Manufacturer – YUHUAN Precision Double Disc Grinder YHDM580B YHDM580B/3 YHDM580B/5 – Maiouke , The product will supply to all over the world, such as: Islamabad, Las Vegas, Frankfurt, Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !Please your inquiry for more details or request for dealership in selected regions.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.